Despite being a cornerstone of Australia’s economy, the country’s steel manufacturing industry is currently facing a critical juncture amid intense global competition.

Professor Cori Stewart, CEO of the Advanced Robotics for Manufacturing (ARM) Hub, says the country’s productivity is at a 60-year all-time low, with the steel manufacturing industry at the epicentre of these challenges.

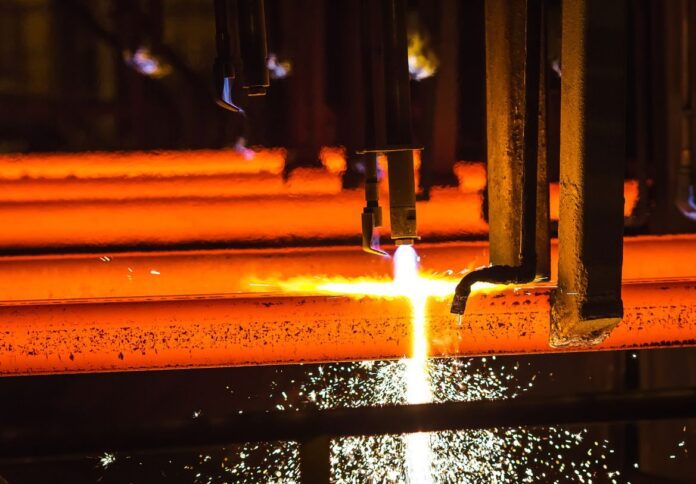

Australia’s manufacturing landscape today, particularly steel manufacturing, is a mix of traditional practices and emerging technologies. And while it continues to produce high-quality products, the entire sector still finds itself grappling with a multitude of issues, such as rising energy costs, environmental regulations, and an ever-increasing need for efficiency.

Professor Stewart says these challenges mean companies need to move beyond “business as usual” and adopt innovative strategies to be globally competitive. According to her, the answer lies in fully embracing the critical role of artificial intelligence (AI) and automation in Australia’s steel manufacturing sector.

Driving competitiveness and growth

It goes without saying that AI and automation are no longer just buzzwords in manufacturing. They are not just merely enhancing existing processes, but revolutionising the entire landscape. AI-driven systems can optimise production schedules, predict maintenance needs, and enhance quality control, leading to significant cost savings and increased productivity. Automation, on the other hand, eliminates the need for humans to handle dangerous or repetitive tasks, enhancing worker safety and freeing up human resources for more complex, value-added activities

“In the highly competitive steel industry, AI and automation is helping Australia realise business growth and competitiveness, commercialise research and development, address skills shortages, and compete in an economy that is rapidly decarbonising,” says Stewart.

Capitalising on green energy demand

The transition to a low-carbon economy presents both challenges and opportunities for the Australian steel industry.

According to the ARM Hub executive, the continuous growth in the manufacturing industry, particularly in steel production, was likely because of the global shift towards sustainable practices. However, she argued that the industry must embrace technological advancements to fully capitalise on these opportunities.

Addressing productivity challenges

Aside from Australia’s productivity levels being a cause of concern, manufacturers are also facing a low adoption rate of robotics. Out of 38 developed countries, Australia ranks 35th in robot population density in the sector. This represents a substantial gap in technological integration that puts Australian manufacturers at a significant disadvantage compared to their global counterparts.

Such lag in robotics adoption has far-reaching implications. Manufacturers in countries with higher robot density can benefit from increased productivity, improved quality control, and enhanced operational efficiency.

These advantages translate into lower production costs, faster throughput and rollout to market, and greater flexibility in meeting customer demands – all crucial factors in the highly competitive global steel market.

Creating upstream value in Australian manufacturing

Citing success stories in Australia’s AI and robotics integration, Stewart pointed to Boeing Australia’s delivery of the Ghost Bat autonomous warfighting aircraft and the automation of more than 700 Caterpillar, Komatsu, and Hitachi haulage trucks in the Pilbara mines.

“This is the kind of high-value, highly skilled industry Australia needs. We need it to back our steel industry and therefore we need to nurture our local tech capability.”

Looking to the future, Stewart advocates for a shift in focus towards creating upstream value in manufacturing, especially in steel production.

“Often we hear about companies creating downstream value (how they create jobs or attract vocational education training (VET) educated staff or low skilled workers) and we also need to ask different questions about how to create upstream value using highly skilled jobs, jobs that may not even exist yet but will soon; indeed it means companies investing more in high-value skills and high-value products than they are likely to now.”

All for a competitive edge

As a cornerstone of Australia’s manufacturing industry, the steel sector’s performance serves as a barometer for the overall health of Australia’s manufacturing capabilities. The integration of AI and robotics is not just an option; it is a necessity for its survival and growth in an increasingly competitive global market.

To address this crucial topic, leaders of the Australian steel industry will gather at the upcoming Australian Steel Convention 2024 in Brisbane from 8 to 10 September 2024. A highlight of the convention will be Professor Cori Stewart’s presentation titled “Finding Your Productivity Edge with Robots and AI.” For more information, visit steel.org.au.