Media Release by Wayland Additive

Wayland Additive, the developer of the Calibur3 metal additive manufacturing (AM) system, will be present at the upcoming TCT 3Sixty event 8-9 June in Birmingham, UK as the sponsor of the Connect Lounge in Hall 9 (E90). The show offers an exciting opportunity for Wayland to discuss its innovative metal AM technology with UK customers, and to highlight its applicability to a range of industrial production applications.

Peter Hansford, Business Development Director at Wayland says, “Since coming out of the pandemic lockdowns, and as shows re-boot across the world, Wayland has been busy visiting customers and prospects, and travelling to events across the world. With TCT 3Sixty, we are delighted to commit to our first fully fledged UK-based event. While we have met with a number of UK companies at our launch events in Huddersfield last year, there is nothing like the ability to meet a well-qualified and substantial audience as we expect to do at TCT.”

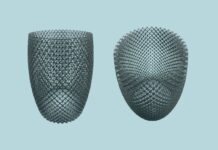

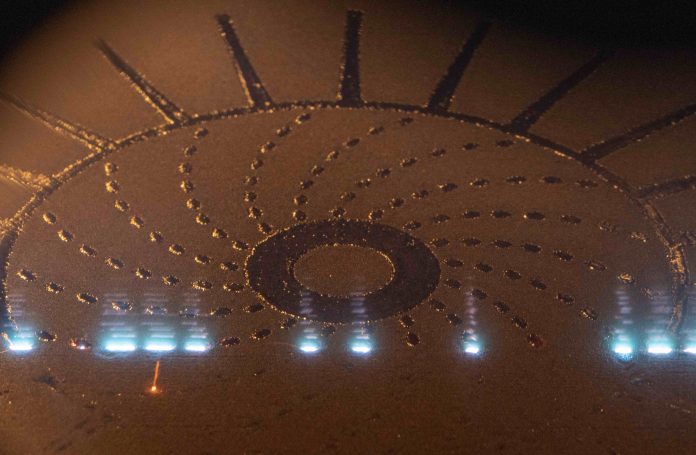

The NeuBeam® process offers a completely new approach to eBeam powder bed fusion (PBF) metal AM technology that represents a big step forward compared with existing PBF systems. The technology overcomes the compromises that most companies have to contend with when using the PBF fusion process with either lasers or eBeams for metal materials. As a result, design engineers can revisit applications that were previously seen as troublesome or impossible and/or begin development projects with a clearer view of the process and the possibilities that can now be realised.

Neubeam® effectively neutralises the charge accumulation generated by an electron beam. This offers greater flexibility than laser PBF while overcoming the stability issues of eBeam PBF. In addition, this means that the NeuBeam® process enables metallurgical requirements to be tailored to application requirements rather to maintain the print process within the narrow bounds permitted by the process. These process capabilities, along with the greatly improved ease of process development, also opens up the use of a much wider range of metal materials.

Hansford continues, “We are all excited by what the Calibur3 opens up for industry through the use of metal AM for production, and members of our team will welcome visitors at the TCT 3Sixty Connect Lounge where we will be gathered to discuss new applications. NeuBeam® is a hot part process rather than a hot bed process. This efficiently creates parts that are free of residual stresses because the high temperatures are only applied to the part and not the bed, ensuring free-flowing powder post-build (no sinter cake) and stress-free parts with reduced energy consumption.

Furthermore, the process overcomes many of the limitations for manufacturing large components – no residual thermal stresses, no gas cross-flow, and a much simpler powder removal process than existing eBeam systems. With Neubeam® there is no need for structural supports (or the use of EDM to remove them), or specific build plates, meaning time and money spent on post-processing is vastly reduced. There are also faster warm-up and shorter cool-down times meaning improved productivity. We can run through in detail what this open ups for you at TCT 3Sixty, and look forward to discussing how the Calibur3 can help you in your manufacturing endeavours moving forward.”

Image Supplied: www.waylandadditive.com