Digital manufacturing company Velo3D announced the latest release of Flow 5.0, a print preparation software that features a new graphical merging capability enabling operators to calculate build times for builds of different part quantities more quickly.

Engineers using Velo3D’s new solution can gain access to a wide range of new features, including user-selectable core parameter sets that offer improved control over overbuilds and the ability to assign different parameters to any part on the build plate, according to a media release.

The company says that this improvement, in addition to Flow’s ability to apply skin and contour overrides, gives customers enhanced control over the final material properties of printed parts.

Alexander Varlahanov, VP of Engineering at Velo3D, said that through the software, the company was able to develop its manufacturing capabilities based on the needs and suggestions of customers.

“By enabling selectable core parameters for customers, engineers can modify the material properties of their parts to better suit the need of the application, including more isotropic parts,” Varlahanov expounded.

Furthermore, the new Flow 5.0 released includes checks and messages that identify possible errors before a build starts, which according to the company reduces the likelihood of customers experiencing failures in their builds.

Velo3D says this allows customers to be confident that a part will print successfully before the process begins.

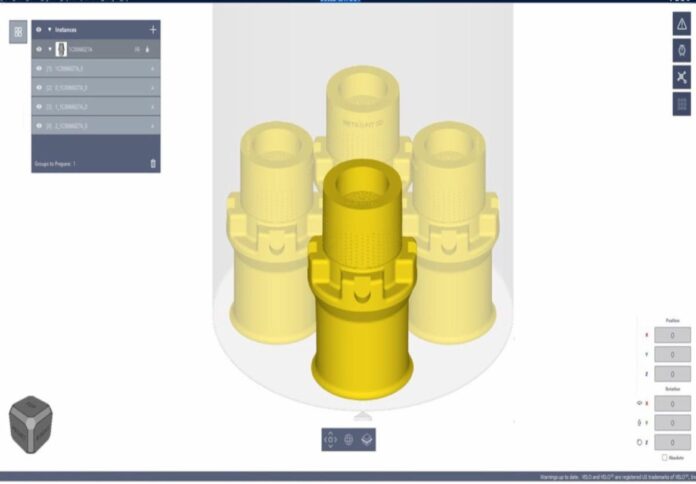

Labelling for items is now included in the flow, and to properly identify and label instances of their parts, customers can quickly add alphanumeric characters, such as serial numbers or other distinctive identification text, to their builds within the Flow print preparation software.

A new Label Updater tool can also be used to update the characters after the print file has been created, according to the company.

Meanwhile, the release also enables a faster method to calculate build times for builds of different part quantities.

After a part has been prepared for print, users can vary the quantity of the part and see updated build times to better understand the economics of scaled production.

The company says this enables contract manufacturers to speed up the quoting process and accelerates OEM planning and scheduling.