Researchers from the Washington State University have discovered how to stretch metal films used in flexible electronics to twice their size without breaking.

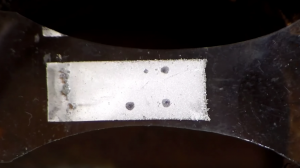

The metal film was created by bonding indium – which is a soft and relatively inexpensive metal – with a layer of plastic.

According to the official announcement by the University, the discovery has the potential to lead to significant improvements because it addresses one of the biggest challenges in flexible electronics.

The work was led by Rahul Panat and Indranath Dutta, researchers in Voiland College’s School of Mechanical and Materials Engineering, and graduate student Yeasir Arafat.

For years now researchers have tried to design and manufacture the tiny metal connections that go into flexible electronics. Current flexible metal research involves tiny springs — which require too much space and electricity — or metals like gold, which is expensive, or copper, which cracks after expanding by about 30 percent. The tiny metal springs have to be able to stretch and still maintain connectivity and require complicated design and high-density circuitry.

“The circuitry ends up requiring a ton of real estate and bulky batteries,” said Panat.

The scientists found that the indium metal film can be stretched to twice its original length and when the pieces broke, it was actually the plastic layer that failed, not the metal.

“This is a quantum improvement in stretchable electronics and wearable devices. A metal film doubling its size and not failing is very unusual. We have proposed a model for the stretchy metal but much work is needed to validate it. It’s a good situation to be in,” added Panat.

The researchers have filed for a patent and published their findings in Applied Physics Letters.

Check out the video below.