Researchers from the University of Queensland have introduced a new 4D printing technology that is capable of producing shape-shifting liquid metals for soft robotics.

4D printing is defined as an extension of 3D printing where solid objects are produced using materials that can change shape when exposed to certain stimuli such as heat, water, or light.

Researchers from UQ’s Australian Institute for Bioengineering and Nanotechnology (AIBN) are printing 4D structures using new liquid metal polymers that can be coaxed into performing a range of mechanical tasks with infrared lasers.

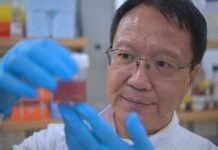

Lead researchers Dr Liwen Zhang and Dr Ruirui Qiao said their lab has developed a unique preparation method to produce 4D designs that are solid and durable while also being able to bend, grasp, lift, and release items five times their weight, or revert to a pre-programmed shape.

The method enables engineers to produce smart liquid metals that can be shaped and prompted to change over time without needing wires or circuits.

“4D printing takes traditional 3D printing and adds a new dimension – the dimension of time,” said Dr Zhang. “This is a new era for robotics applications and a gamechanger for additive manufacturing.”

4D printed objects are usually prepared with a 3D printer using specific ingredients that give the finished product new qualities and abilities.

In their paper published in the journal Nature Communications, Zhang, Qiao, and colleague Professor Tom Davis explained how they used spherical liquid metal nanoparticles to prepare printing resins that are responsive to near-infrared light.

This means lasers can be used to guide the materials to bend, grab, and release items.

Despite the method being in its early stages of development, Qiao said it presents great potential for designing soft robotics, or technologies that mimic natural movements and interactions.

The technology could also play a role in several applications, ranging from aeronautical engineering to medical device manufacturing.

Qiao also noted that the ability to customise and shape materials after they had been printed would lead to wider manufacturing breakthroughs and consumer innovations, from climate-reactive clothes and building materials to self-assembling furniture.

“The early signs for this technology are incredibly promising, and the wide range of potential applications give us encouragement to continue our research,” Qiao said.