Researchers at The University of Queensland (UQ) have developed an innovative technology that removes harmful ‘forever chemicals’ from water and repurposes them for use in renewable batteries.

The breakthrough, led by scientists at UQ’s Australian Institute for Bioengineering and Nanotechnology (AIBN), could potentially revolutionise clean energy technology, as revealed in a media release.

The newly developed filter targets per- and polyfluoroalkyl substances (PFAS), a group of synthetic chemicals notorious for their persistence in the environment and potential health risks.

The filter utilises a patented sorbent solution that employs an ion-exchange technique to effectively isolate and remove PFAS particles from water as it passes through the system.

Dr Cheng Zhang, a polymer chemist involved in the project, highlighted the dual benefits of this technology.

“People are increasingly aware of the risks that PFAS poses to human health, and how long these chemicals persist in the natural environment,” said Dr Zhang.

“Not only does our filter technology remove harmful particles from water, those captured chemicals are available to be repurposed to help decarbonise the planet.”

Dr Zhang further explained the potential of fluorine-based materials harvested from the filter in enhancing clean energy technology.

“The increasing demand for high-performance rechargeable batteries means manufacturers are constantly searching for new materials that improve the energy density, safety, and cycling stability of batteries. Recycled PFAS has excellent properties for this purpose,” he added.

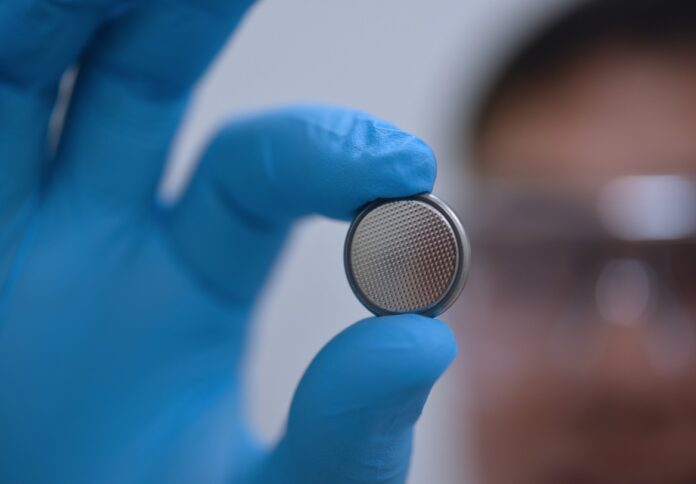

The team has tested a prototype of the PFAS filter in a laboratory setting and is preparing to commence pilot testing in Brisbane and the United States.

The project has received $1 million in funding from the Advance Queensland Industry Research Projects program.

Pilot testing is scheduled for various locations, including the Luggage Point Sewage Treatment Plant, in collaboration with water management company GHD, project management firm OCTA, and the Queensland Department of Environment, Science and Innovation.

An additional pilot site is planned for the second year of the project to scale up testing.

“These demonstrations will be pivotal to scaling up our filter technology for use in industrial water infrastructure,” Dr Zhang noted.

He added, “If this testing goes as we believe it will, we hope to reach commercial production within three years.”

PFAS chemicals, commonly used in consumer and industrial products for their heat, stain, grease, and water resistance, have been linked to various potential human health problems due to their persistence in the environment.