University of New South Wales engineers have developed a 3D printing process using solid-state polymer electrolytes (SPE) for energy storage.

The research team from the UNSW’s School of Chemical Engineering said processing such material could potentially enhance the development of a future that involves small, intricately designed energy storage.

In a paper published in Advanced Materials, the team, led by Professor Cyrille Boyer, said their 3D printed solid polymer electrolyte offers high conductivity, as well as robust strength. This means the material can be used as the actual structure of a device, creating a range of conceivable design opportunities, particularly for future medical products.

In a media statement, UNSW Sydney explained that solid-state electrolytes have traditionally suffered from poor performance, which is due to low ionic conductivities or poor mechanical properties.

“Nobody has 3D printed solid polymer electrolytes before. Traditionally they have been made using a mould, but previous processes did not offer the ability to control the strength of the material, or to form it into complex shapes,” says Kenny Lee, research and development chemical engineer focused on polymers and elastomers manufacturing at UNSW.

According to Lee, the UNSW team has achieved increased mechanical strength without compromising conductivity, leading to the printing of materials with sophisticated geometries,

In the research paper, SPE was described as composed of nano-scale ion-conducting channels embedded in a rigid crosslinked polymer matrix. The material is produced through a process known as polymerisation-induced microphase separation.

“We can create really tiny structures with the kind of systems we’re using. So it has fantastic application in nanotechnology and anywhere you need to design energy storage on a micro-scale level,” Lee said.

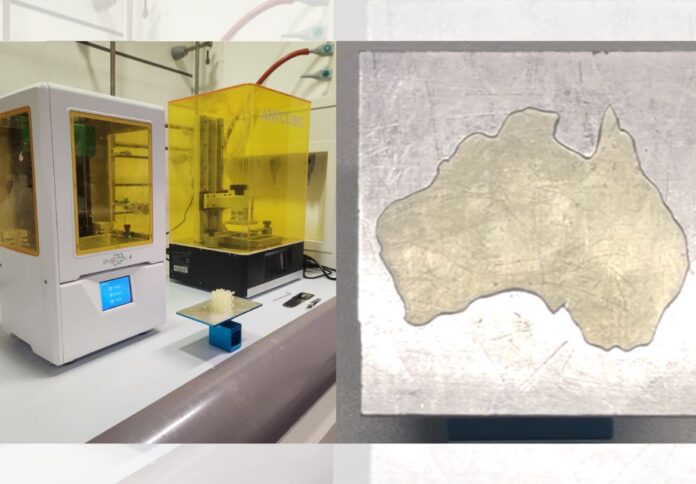

To showcase the material’s versatility, UNSW researchers printed an intricate map of Australia, which was then tested as an energy storage device.