Engineers from UNSW Sydney have developed a way to build flexible electronic systems using ultra-thin skin-like materials in an effort to improve the efficiency of organ-on-chip technology.

The advancement makes it possible for entire 3D structures to function similarly to a semiconductor and could greatly lessen the demand for animal testing, the university said in a media release.

Later on, the researchers said the technology might also be utilised in implanted biomedical applications or wearable health monitoring systems, such as a device to warn epileptics of an impending seizure.

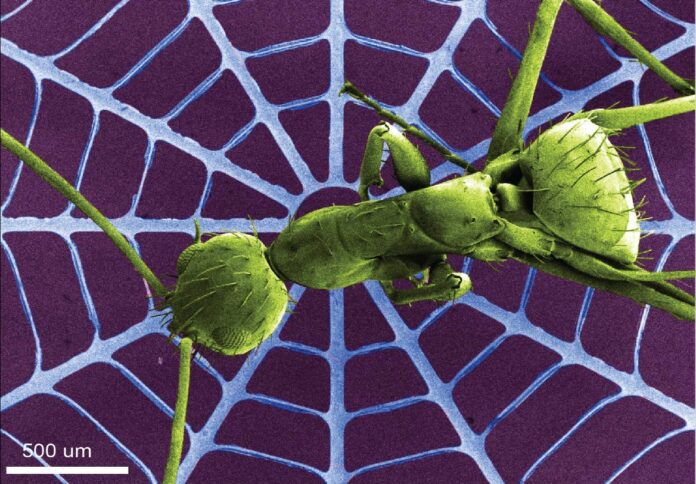

The new process involves using lithography – a technique that uses light to print tiny patterns – to create broad bandgap semiconductors such as silicon carbide and gallium nitride onto very thin and flexible nanomembranes on a polymer substrate.

These semiconductor membranes can be bent and stretched into any imaginable 3D shape while still functioning as sensors, recorders, and stimulators.

The research team argued these might play a significant role in organ-on-chip technology, a cutting-edge strategy that involves building microscopic replicas of human organs on tiny chips.

Lead researcher Dr Hoang-Phuong Phan expressed the need to develop 3D electrodes to help facilitate that organ-on-chip process.

“Many people are keen to move towards medical testing on replicated versions of human cells rather than live animals for legal, ethical and moral reasons,” Dr Phan said.

Phan added, “Our process allows for an electronic system to be created on a membrane that can be stretched into any 3D shape around the organ-on-chip.”

The researchers believe this application could turn into a commercial product within three to five years, though they intend to perform extra work to strengthen the device and include additional components such as wireless communication.

In terms of utilising the technology in wearable health monitoring systems, Dr Phan says there is interesting potential for the new process to significantly improve the quality of monitoring, diagnosis, and therapy.

One such function may be a worn sleeve that detects and signals alarms about the levels of UV radiation a person is exposed to throughout the day, potentially lowering the incidence of skin cancer.

Dr Phan believes that using the technology in wearable health monitoring devices has the potential to dramatically improve the quality of monitoring, diagnosis, and therapy.

The study team’s findings have been published in the Advanced Functional Materials journal under the direction of Dr Hoang-Phuong Phan from UNSW’s School of Mechanical and Manufacturing Engineering.

The work is the pinnacle of interdisciplinary, cross-institutional collaboration between UNSW, Griffith University, UQ, QUT, and their international partners such as Kyung Hee University, University of Southern California, and Northwestern University.