Scientists at UNSW Sydney have devised a new technique to improve the efficiency and cost of hydrogen fuel cells in a push to increase access to clean fuel.

In a new study, published in Energy & Environmental Science, a team of researchers created a novel method to test the durability and stability of platinum alternatives, which will provide fresh insights into cost-effective choices for hydrogen fuel cells.

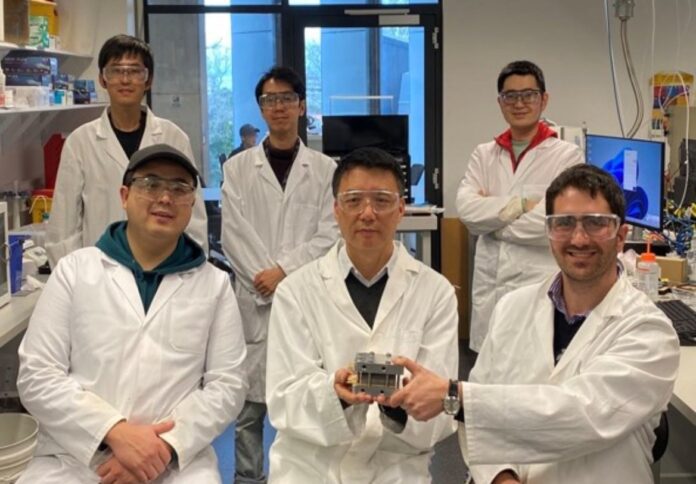

Several aspects are being addressed by experts from UNSW’s School of Chemistry, including Professor Chuan Zhao, Dr Quentin Meyer, and Mr Shiyang Liu, in order to boost the commercial viability of hydrogen fuel cells.

According to researchers, there are concerns with the price and availability of some of the essential components of a hydrogen fuel cell, such as platinum, which is frequently utilised as the catalyst required to start the process.

“Platinum is always going to be expensive because there isn’t a lot out there,” said Pro Zhao.

“So, we need to explore alternatives, whilst also providing a quick and easy way to measure how well these new materials are working in hydrogen fuel cells,” he added.

In particular, hydrogen fuel cells, which were invented in the nineteenth century as a green energy source, use chemical reactions to split hydrogen into protons and electrons, creating electricity and water.

Dr Meyer explained the chemical reaction process and underscored that the primary distinction between hydrogen fuel cell technology and batteries is that hydrogen fuel cells do not require charging.

Instead of a petrol pump, there is a hydrogen pump, and refuelling a hydrogen fuel cell car takes only three minutes, Meyer noted.

According to the team, the procedure is not only regarded as a clean source of energy because it only generates water as a byproduct, but it is also environmentally friendly.

Although it does not exist naturally, hydrogen is a relatively plentiful element that can be produced from water, researchers noted.

The expense of the catalyst, according to the researchers, is yet another significant issue. Researchers predict that when fuel cells and hydrogen production both increase, their prices will decrease.

To address the problems already present in the sector, Prof Zhao, Dr Meyer, and their team developed a technique to comprehend why some catalyst materials are not as stable as platinum.

“Using three novel methods that we tested in the lab, we can quickly figure out how stable our platinum-free fuel cell is and most importantly understand why,” Prof Zhao explained.

He continued by saying that scientists in other labs may readily adopt this strategy to quickly and accurately understand how effective their fuel cells and catalysts are.

Using these methods, the team discovered that during the first 10 hours of running the fuel cell, the loss of iron active sites causes up to 75 per cent of the iron-based active sites – the particular regions where the reactions happen – to become inactive.

“By allowing precise tracking of the degradation mechanisms, we expect that the research field will be able to make new materials targeting these stability issues,” Dr Meyer said.

“As a result, we believe our approach will help improve the stability of platinum-free catalysts and give this field a brighter future,” he added.

While this is a major step in the field of hydrogen fuel cells, the team is also working on ways to improve the scalability of the low-cost, platinum-free hydrogen fuel cell catalyst from the lab to a product that can power actual gadgets and, one day, power transportation on our roads.