Image credit: www.newcastle.edu.au

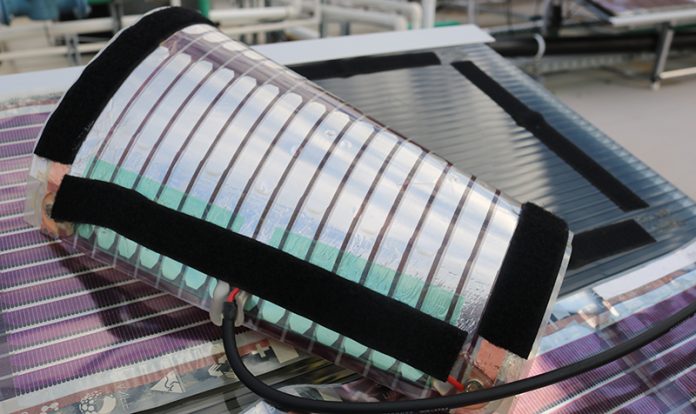

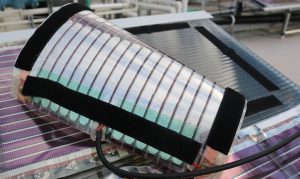

The University of Newcastle unveiled its first printed solar demonstration site last week, which UON Professor Paul Dastoor believes could promote Australia as a global leader in printed solar in the coming years.

Image credit: www.newcastle.edu.au

Covering an area of one hundred square metres, UON’s new solar demonstration site is only the third installation of its kind in the world.

“There are just three demonstration sites at this scale that we know of anywhere in the world, so Australia has joined quite an elite group of global leaders poised to make this technology a commercial reality,” Professor Dastoor said.

He said the lab-scale printer on site enables rapid material manufacturing, allowing for accelerated deployment into the marketplace.

“No other renewable energy solution can be manufactured as quickly. On our lab-scale printer we can easily produce hundreds of metres of material per day, on a commercial-scale printer this would increase to kilometres. If you had just ten of these printers operating around the clock we could print enough material to deliver power to 1000 homes per day,” the Professor explained.

“The low-cost and speed at which this technology can be deployed is exciting, particularly in the current Australian energy context where we need to find solutions, and quickly, to reduce demand on base-load power.”

The material is made by printing an advanced electronic ink onto paper thin, clear laminated sheets using conventional printing presses. Importantly, both the electronic ink and printing process have been pioneered by Professor Dastoor’s UON team.

“On the back of five years of in-house development, all of the components of these advanced electronic inks are now synthesised at scale within our Centre for Organic Electronics using non-toxic carbon-based materials,” Mr Dastoor remarked.

“These components are then used directly or further processed into water-based inks and paints.”

He said the technology delivers ‘unprecedented affordability’ at a production cost of less than $10 a square metre, adding that a new service delivery model could round out the innovation process, removing key barriers to solar uptake in the community.

“It might operate like a telephone line, where customers choose a service plan based on their usage requirements but do not need to outlay the physical cost of the line installation and associated upkeep. The system is owned, maintained and updated by the provider and customers could scale their plan up or down as their requirements change,” Professor Dastoor explained.

“By reinventing the delivery model we remove the need for initial lump sum outlays, overcoming the key barrier to community uptake and ensuring that the science actually ends up on our rooftops.”

This portable technology, which Mr Dastoor described as ‘ideal for applications in countries where people still have no access to electricity’, has already attracted global logistics solutions company CHEP as its first commercial partner.

CHEP Australia’s Senior Manager Lachlan Feggans said the two parties are already working together to rollout a commercial scale pilot installation of organic printed solar on the roof of one of its service centres next financial year.

“Through our collaboration with UON, we see the potential to make CHEP’s inherently sustainable business model even better. Our aim is to develop better supply chains, but we recognise that this begins with sustainability in our own operations,” Mr Feggans concluded.