Researchers at the University of Michigan have pioneered a novel fabrication process for helical metal nanoparticles using 3D printing technology, aiming for a simpler, more cost-effective method for the rapid production of materials crucial for biomedical and optical devices.

Nicholas Kotov, the Irving Langmuir Distinguished University Professor of Chemical Sciences and Engineering at the University of Michigan and co-corresponding author of the study published in Proceedings of the National Academy of Sciences, expressed the motivation behind the research.

“One of our motivators is to drastically simplify manufacturing of complex materials that represent bottlenecks in many current technologies.”

Chiral surfaces, characterised by their lack of mirror symmetry and ability to bend light at the nanoscale, are highly sought after.

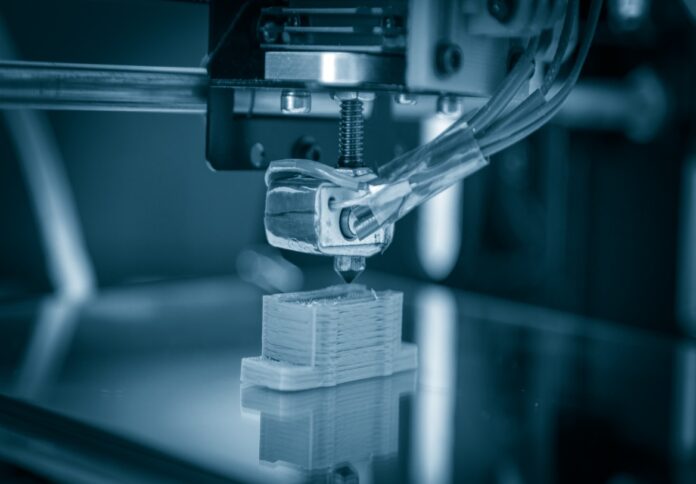

The study showcases a method to produce these surfaces by 3D printing ‘forests’ of nanoscale helices. Aligning the axes of these helices with a light beam results in strong optical rotation, enabling the harnessing of chirality in various health and information technologies where chirality plays a vital role.

Chiral surfaces from plasmonic metals are particularly desirable as they can serve as highly sensitive biodetectors capable of detecting specific biomolecules associated with dangerous drug-resistant bacteria, mutated proteins, or DNA.

Additionally, these materials hold promise for advancing information technologies by enhancing data storage capacities and processing speeds through the interaction of light with electronic systems, such as fibre optic cables.

While the demand for these specialised 3D-structured surfaces is high, traditional manufacturing methods are complex, expensive, and generate significant waste.

Most commonly, these materials are produced using highly specialised hardware available only in a few high-end facilities.

However, the University of Michigan research team has developed a method using helical light beams to fabricate nanoscale helices with specific handedness and pitch, offering a more accessible and efficient approach.

Commenting on the breakthrough, Kotov remarked, “Centimeter-scale chiral plasmonic surfaces can be produced within minutes using inexpensive medium-power lasers. It was amazing to see how fast these helical forests grow.”

This work, funded by several organisations including the US Department of Defense and the National Science Foundation, holds promise for advancing additive manufacturing and facilitating the production of complex nanoscale architectures for the next generation of optical chips.

The research involved a team of the University of Michigan co-authors, including Connor McGlothin, Minjeong Cha, Zechariah J. Pfaffenberger, Emine Sumeyra Turali Emre, Wonjin Choi, Sanghoon Kim, and Julie S. Biteen.