In a collaborative effort spearheaded by the University of South Australia (UniSA), with industry partners VPG Innovation and SMR Australia, a project is underway to revolutionise optical components for Earth observation through additive manufacturing.

The firms aim to advance a novel optical manufacturing process and materials suitable for space flight applications, according to an iLAuNCH media release.

This initiative seeks to move beyond the conceptual stage, transforming a 2021 Defence Innovation Partnership (DIP) concept demonstrator into a fully realised, production-grade manufacturing initiative.

Satellite optical payloads play a crucial role in monitoring Earth’s dynamic changes, ranging from environmental shifts and transportation activities to infrastructure development and defence Intelligence, Surveillance, and Reconnaissance (ISR) operations.

However, the limitations of traditional glass optics on satellites, hindered by conventional manufacturing processes, are being addressed through an ambitious project called iLAuNCH Trailblazer.

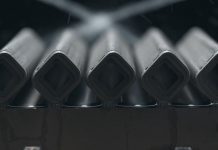

The innovative approach involves the incorporation of freeform optics technology, made possible by the emergence of additive manufacturing technologies.

Unlike traditional optics constrained by symmetry, freeform optics, such as mirrors, can now be intricately designed and additively manufactured to accommodate complex shapes.

This capability enhances the field of view within reduced packaging sizes, withstanding the rigorous conditions of space.

Darin Lovett, executive director of iLAuNCH Trailblazer, highlighted the project’s essence, stating, “This project demonstrates what iLAuNCH is all about, taking a 2021 Defense Innovation Partnership (DIP) concept demonstrator that investigated the viability of Freeform Optical Components for small satellites – and moving it into production using Australian technology for real-world application.”

A key challenge in developing freeform optics lies in achieving an optical-grade finish and a stable, durable coating suitable for the demanding low Earth orbit environment.

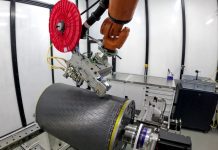

UniSA’s Future Industries Institute has played a pivotal role in pushing the boundaries of additive manufacturing to develop groundbreaking technology.

Dr Kamil Zuber, senior research fellow at UniSA, affirmed, “We are developing an optical grade finish on additive material substrates for optical components for satellites.”

In particular, the collaborative effort brings together the expertise of UniSA, VPG Innovation, and SMR Australia, combining traditional and additive manufacturing capabilities along with advanced injection moulding and coating expertise.

Al Jawhari, co-founder and Group CEO of Stärke-AMG, expressed enthusiasm about the project’s potential impact on space exploration and satellite optics design.

He stated, “We firmly believe in the transformative power of additive manufacturing and its potential to positively reshape the manufacturing industry.”

Dr Bastian Stoehr from SMR Australia emphasised the significance of collaboration, noting, “Our combined efforts will redefine the possibilities in additive manufacturing and freeform optics, promising a transformative impact on the future of space exploration.”

The project, besides enhancing ISR capabilities for space satellites, will also validate space-grade materials and coatings for optical and structural satellite components.