The University of Illinois Urbana-Champaign (UIUC) has added a new additive manufacturing machine by Continuous Composites to its campus in an effort to print large and lightweight structural composites like those used in aerospace structures.

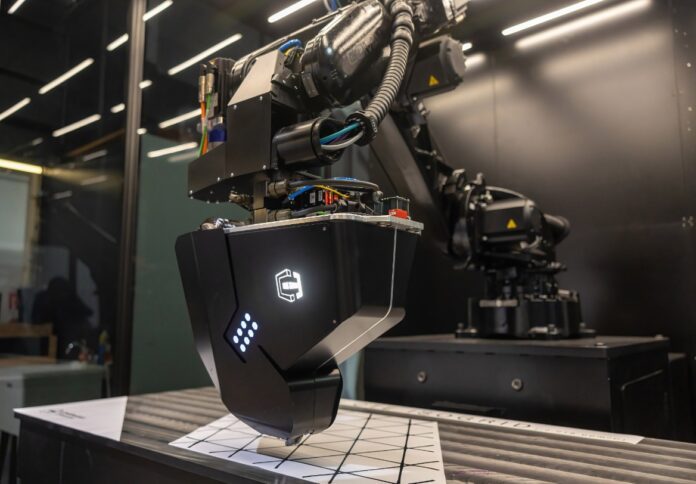

Called the CF3D printer, the university described it as the first continuous fibre 3D printer to be installed in academia and outside the company by Continuous Composites.

“This is a paradigm-changing composite technology because it allows you to create structures with complex shapes that have mechanical properties approaching those of traditional aerospace composites,” explained Jeff Baur, founder professor of engineering.

He further pointed out that high-performance composites are currently created by manually layering fabric or fibres with resin before heating them for a considerable amount of time in an autoclave.

To date, Baur said researchers can lay the fibres by a robot, snap-cure them into shape, and then cure them in an oven in half the time.

“Due to the strength of the continuous fibres, we believe we currently have the world’s strongest additively printed composite, but there is still a lot of technical work that needs to be done,” the professor noted.

The CF3D printer has a special academic/industry partnership between UIUC and Continuous Composites, Inc, according to Baur.

According to him, the contract with Continuous Composites would provide his lab with some technical support, supplies, and hardware upgrades.

In return, he said, “We’ll provide the company with free and open feedback about our experiences with the equipment so they can make improvements for their future customers.”

Currently, UIUC researchers are creating resin molecules that, under the appropriate conditions, might unzip to make the resin recyclable and the fibres recoverable so that both materials might be used again.

The university said this was done through a recently awarded Department of Energy backed centre, known as RE-MAT, and led by UIUC through the Beckman Institute.

Due to this exploration, the additive printed composite could expedite the development and evaluation of the said new materials and allow a circular economy for thermoset composites.