Fast-charger specialist Tritium has opened a world-class compliance testing facility at its Brisbane headquarters.

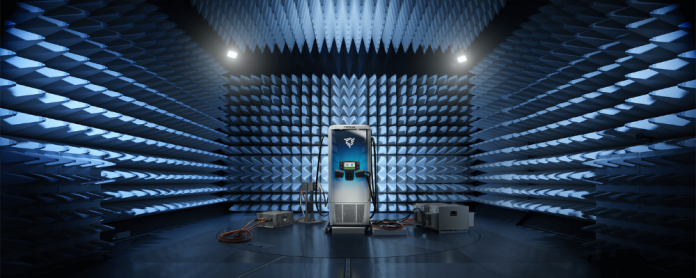

Now viewable through an interactive tour on the Company’s website, the new EV charger testing facility contains one of the world’s largest and highest-powered electromagnetic compatibility (EMC) testing chambers, along with other key test and certification enablers including thermal chambers for testing in extreme temperatures.

Without the benefit of their own EMC testing facilities, many charger manufacturers and developers across the world need to test and certify their chargers in publicly-accessible EMC testing facilities with advance booking notice.

Tritium CEO Jane Hunter said any subsequent need for retesting often requires these manufacturers to return to the queue, which can significantly slow the process to get new charging technology to market.

“As passenger and fleet EVs with larger battery packs come online, demand for higher-powered DC fast chargers is expected to increase. To get these chargers in the ground and installed, each new product line must pass rigorous test standards to ensure compliance with various regulations around the world,” Ms Hunter said.

“The more rapidly we can develop new products to meet the needs of this fast-evolving market and complete testing of those products for public use, the faster we can deliver chargers that meet that demand. This cutting-edge facility is expected to enable us to deliver world-leading charging infrastructure to our customers across the globe.”

Tritium Chief Technology Officer and Co-Founder James Kennedy, said the facility is designed to deliver up to 720kW of regenerative power from its integrated system with fully integrated AC and DC power feeds, ensuring Tritium can test devices that demand very high power levels to Federal Communications Commission (FCC) and International Electrotechnical Commission (IEC) certification requirements.

“We now have the freedom to test a charger at a moment’s notice and for as long as we need, to ensure our chargers not only meet the thresholds required for compliance but exceed them,” Mr Kennedy said.

“We believe that taking away the time constraints of a commercial facility, combined with the ability to test in one of the most powerful and advanced facilities of its kind, will enable us to rapidly create and certify market-ready products more cost-efficiently and to add features and customizations to more effectively meet the needs of our customers.”