As online sellers become more sophisticated in their marketing strategies, the market competition in the marketing sector is becoming increasingly unforgiving to slow adapters. As the adage goes: failing to plan is planning to fail.

Manufacturers who want to avoid plateauing (or worse, disappearing) must be proactive with their digital projects. Once all your online shop’s components are put in place, it’s time to go live.

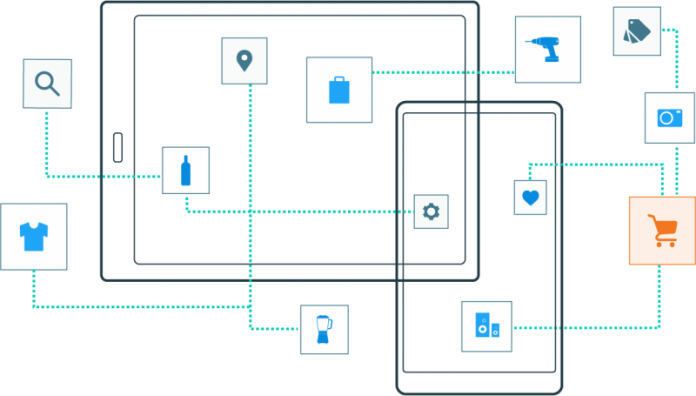

Keeping a dynamic business outlook requires staying true to your online shop’s minimum viable product – that is, the development technique that allows you to attract early-adopter customers while simultaneously driving up product valuation.

The MVP approach combines the smallest-possible project scope with simultaneous functional use of the online. In this way, you get to test out basic ideas among real target audiences, monitor product progress and make a final decision on whether to scale the idea up or junk it.

One thing to note, with MVP you’re starting with limited data. But the journey is the goal here as the MVP allows you to get other necessary information on user experiences and other experience-based findings.

So while you’re rolling fresh new releases, you as the manufacturer can operate in real-time, make adjustments, and continuously improve. That’s dynamism right there.

Customer requirements in B2B manufacturing are ever-changing. Being flexible allows one to replace existing functions or add new services without a tedious overhaul of the entire changes. This enables D2C to respond to pandemic-driven challenges while keeping customers’ trust.

Forward-thinkers always think more than two steps ahead. MVP allows you to measure success based on data and defined KPIs to help you and your developers obtain useful insights. Accordingly, the approach allows you to work in parallel and optimize the data exchange between your User Interface (UI) frontend and server backend.

Innovation, however, is limitless. More and more manufacturers are beginning to harness the power of Smart Manufacturing (SM) and Artificial Intelligence (AI).

Through the predictive network of SM, the Industrial Internet of Things becomes a reality. In SM, customer feedback plays a vital role. Sensors that gather data store information in a database that then works hand-in-hand with smart algorithms to automate processes and sustainably improve data quality.

In manufacturing, you’ll have to focus on inventory management, raw materials, and work-in-progress inventory levels. SM can save you valuable time by handling complex product catalogs in real-time.

With the help of AI and a good database, SM can predict system failures before they happen. This allows you to redirect operational costs towards even more refined customer experiences. By networking eCommerce and production, all actions of the company can be perfectly adapted to the customer.

Nowadays, it is not enough for manufacturers to work hard. Going above and beyond means having the foresight to reach your goals. In a new normal where just about everything is met with uncertainty, Australian manufacturers must take the high-ground, look ahead, and take flexible measures. After all, the manufacturing sector is constantly evolving at a pace and way we have yet to uncover.