Tag: Paul Runyan

The role of micro moulding in the production of micro-optics

Micro-optics encompasses components like tiny lenses, beam-splitters, prisms, light-pipes, and other optical parts ranging from 20 microns to 1 mm in size, or larger optical components with micron-level features.

Micro moulding and the future of biomedical applications

In the dynamic medical field, micro moulding has increasingly become the foundation for innovation, particularly in the creation of cutting-edge biomedical devices.

Design guidelines for micro moulding

When you begin to assess the use of micro injection moulding, partnering with a specialised sub-contract manufacturer becomes a strategic asset. This partnership should be strong for the entire journey of your product, from the blueprints to high-volume production, all development preferably taking place under a single roof.

The importance of material selection in micro moulding applications

In the precision-demanding realm of micromoulding, the selection of appropriate materials is not merely a step in the manufacturing process, it’s the cornerstone upon which the performance and reliability of the final product rest.

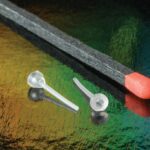

Injection molding of thin wall cannulas — A lesson in expertise & persistence

After 5 years of painstaking work, leading micro molding innovator Accumold has developed a way to micro injection mold thin wall cannulas in very high volumes.