The University of Sydney has announced the launch of its new Biomanufacturing Incubator, a cutting-edge initiative aimed at transforming the field of biomanufacturing by bridging the gap between biological research and industrial application.

The incubator will unite cell biologists and bioprinting experts to develop innovative solutions in fields ranging from cardiovascular health to diabetes treatment, the university said in a news release.

The Biomanufacturing Incubator is set to revolutionise medical research by integrating 3D bioprinting with cell biology. Biomanufacturing, which uses 3D bioprinting to create organoids and cell models that mimic natural tissue, has traditionally been limited by a “one size fits all” approach.

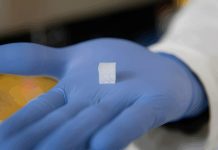

This method involves printing cells within biomaterial scaffolds, offering only basic tissue cues. The incubator aims to push the boundaries of this technology, allowing for more sophisticated and personalized applications.

Led by Professor Steven Wise, a cardiovascular bioengineering researcher and National Heart Foundation Future Leader Fellow, and Associate Professor Khoon Lim, a biomedicine researcher and Australian Research Council Future Fellow, the Biomanufacturing Incubator represents a multidisciplinary effort to unify various research areas within the University of Sydney.

The goal is to foster a “biomanufacturing way of thinking” that can drive meaningful progress toward engineering human organs and advancing treatment options for a range of diseases.

Industry potential

Biomanufacturing has long been touted as a technology capable of engineering human organs for transplantation.

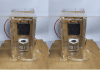

However, as Professor Wise points out, the field has yet to deliver on its early promises. “What’s big in our field right now is a combination of 3D bioprinting with cells,” said Professor Wise.

He added, “But we’re far from what it promised us, which was if you have a heart attack, we’ll bring you a new heart.

The industry’s current model involves companies selling 3D bioprinters to individual researchers or labs, who then work in isolation.

This siloed approach has hindered the translation of research into commercialised products.

“There’s little translation of this research into commercialisation,” said Professor Wise. “It’s hard to progress new ideas down the translational pathway because there’s no unified effort where everyone is working together.”

The incubator aims to change this by leveraging the University of Sydney’s existing strengths in cell culture and clinical trials.

“We’ve got the best scientists who do cell culture in their respective disciplines, and close links to Local Health Districts and teams who conduct clinical trials,” Professor Wise explained.

“We’re in a perfect storm—everything has fallen into place, and all I did was come along and connect the dots.”

A multidisciplinary approach

The success of biomanufacturing hinges on multidisciplinary collaboration. “If you’re going to move towards making an off-the-shelf pancreas or a place where beta cells can grow and cure diabetes, you need engineers and chemists, but you also need the best diabetes people,” said Professor Wise.

The Biomanufacturing Incubator will bring together cell biologists from the Faculty of Medicine and Health who specialise in various fields, including vascular systems, facial reconstruction, eyesight, dentistry, and diabetes.

These experts will collaborate with bioprinting specialists to innovate within a “biomanufacturing way of thinking.” The goal is to unlock the full potential of bioprinting, a technology that has so far only shown a fraction of what it can achieve.

One of the biggest challenges in biomanufacturing is ensuring that printed materials are safe for human use, according to the university.

Currently, 3D bioprinters are limited to a narrow range of materials that can sustain living cells. The incubator will focus on developing new bioinks and gels that can support a wider variety of cells, including those used in treating diseases like diabetes.

“We want to get through these early barriers and showcase the value biomanufacturing can add to the work of non-bioprinting researchers,” said Associate Professor Lim.

“We’re doing this because we want to fundamentally transform a disease state. We want to go after big ideas like a cure for diabetes.”

Looking toward the Sydney Biomedical Accelerator

Professor Wise co-chairs the biomanufacturing working group for the Sydney Biomedical Accelerator (SBA), a visionary partnership between the University of Sydney, Sydney Local Health District, and the NSW Government.

The SBA, set to open in 2027, will be a world-leading health, education, and biomedical research complex in Sydney.

The working group, which includes experts from science, medicine, engineering, and the Sydney Local Health District, has designed advanced biomedical manufacturing facilities for the SBA.

These facilities will integrate fundamental, pre-clinical, and clinical research with expertise in biomedical and tissue engineering and advanced manufacturing.

“This will be a great space with cutting-edge printers and will sit alongside dedicated labs and spaces for startups and industry collaboration,” said Professor Wise.

“We are two or three years out now, so it’s time to tap into a translational mindset, so we are ready to make the most of the opportunities on offer when the SBA opens.”

The Biomanufacturing Incubator will complement existing research programs and collaborations in drug discovery, organoid innovation, and core research facilities such as Sydney Analytical.

It adds another critical element to the University’s strength in biomanufacturing and positions Sydney as a global leader in this emerging field.

From incubator to impact centre

The success of the Biomanufacturing Incubator builds on the momentum of previous initiatives at the University of Sydney.

After two years of impactful research, the Heat and Health Research Incubator has now transitioned to an Impact Centre, rebranded as the Heat and Health Research Centre (HHRC).

The HHRC, led by Professor Ollie Jay, continues to focus on reducing the impacts of extreme heat on human health and society by bringing together a multidisciplinary team of researchers, policymakers, industry professionals, and healthcare experts.