A group of researchers from the University of Sydney have successfully biodegraded a commonly used and hard-to-recycle plastic, called Polypropylene, using two strains of fungi.

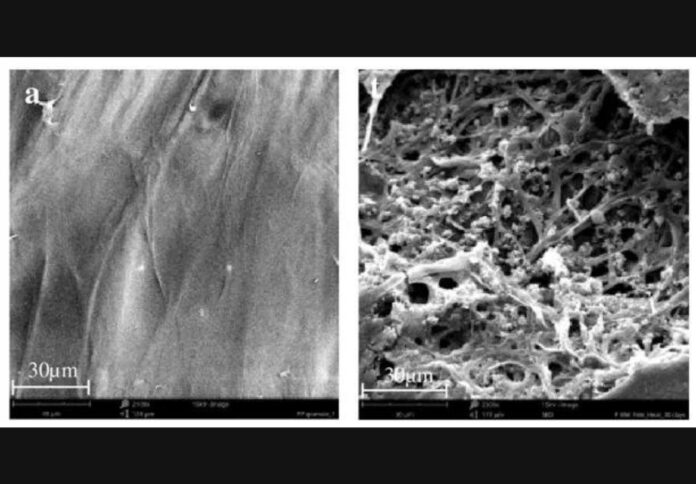

The two strains used in the study, namely Aspergillus terreus and Engyodontium album, were able to break down the polymer after it had been pre-treated with either UV light or heat, reducing the plastic by 21 per cent over 30 days of incubation, and by 25 to 27 per cent over 90 days.

Polypropylene has long baffled environmental researchers, as the material accounts for roughly 28 per cent of the world’s plastic waste, with only 1 per cent of it being recycled.

The material is so rarely recycled because of its short life as a packaging material and often becomes contaminated by other materials and plastics, creating the need for new methods that have a minimal environmental impact.

The researchers seek to use the novel method they developed to reduce the vast amount of plastic polluting the environment and lead to a greater understanding of how plastic pollution might biodegrade naturally under certain conditions.

PhD student Amira Farzana Samat, the study’s lead author from the University of Sydney’s School of Chemical and Biomolecular Engineering, said the vast majority of plastic waste is not adequately recycled, which means most often ends up in the world’s oceans, rivers, and landfill.

“It’s been estimated that 109 million tonnes of plastic pollution have accumulated in the world’s rivers and 30 million tonnes now sit in the world’s oceans – with sources estimating this will soon surpass the total mass of fish,” Samat said.

Proponents of the study are now looking enhance the overall efficiency of degrading polypropylene before seeking investment to scale the technology and develop a small-scale pilot prototype for commercialisation.

The team has isolated other microorganisms from the marine environment and used a similar process to degrade marine plastic waste, with preliminary results showing even high degradation.

“We need to support the development of disruptive recycling technologies that improve the circularity of plastics, especially those technologies that are driven by biological processes like in our study,” said Professor Ali Abbas, Samat’s PhD supervisor and molecular engineering and chief circular engineer at Circular Australia.

“It is important to note that our study did not yet carry out any optimisation of the experimental conditions, so there is plenty of room to further reduce this degradation time,” Professor Abbas added.