Image credit: Stratasys/Business Wire

3D printing giant Stratasys has unveiled a new additive manufacturing solution for low volume production and mass customisation at the RAPID + TCT Show in Pittsburgh.

Image credit: Stratasys/Business Wire

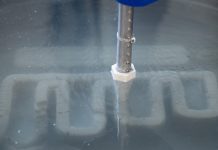

Still under development, the Stratasys Continuous Build 3D Demonstrator is composed of a modular unit with multiple 3D print cells working simultaneously and driven by a central, cloud-based architecture.

Stratasys said the new platform is designed to produce parts in a continuous stream with a minimal operator intervention, automatically ejecting completed parts and commencing new ones.

“Each 3D print cell can produce a different job to help enable mass customisation projects. Additional cells can be added at any time to the scalable platform to increase production capacity as demand requires,” the company said in a press release.

“Automatic queue management, load balancing and architecture redundancy further lead to accelerated throughput as jobs are automatically routed to available print cells. If a single print cell fails, the job will be automatically rerouted to the next available cell.”

Stratasys Co-founder and Chief Innovation Officer Scott Crump said target applications include education RP labs and environments that can benefit from zero tooling production and from a zero inventory supply chain.

“The Stratasys Continuous Build 3D Demonstrator is an important milestone in the company’s long term vision to make additive manufacturing a viable solution for volume production environments,” Mr Crump remarked.

“It combines our FDM print quality, GrabCAD control and monitoring, and a new multi-cell, scalable architecture to create a breakthrough manufacturing platform.”

Savannah College of Art and Design is one of the lucky few Stratasys customers that have begun trialling the Continuous Build 3D Demonstrator to enhance their offerings and explore new business opportunities.

SCAD president and founder Paula Wallace described the Stratasys Continuous Build 3D Demonstrator as “the future” of additive manufacturing.

“We believe the Stratasys Continuous Build 3D Demonstrator represents the next generation of 3D printing, the first-ever platform of its kind,” Ms Wallace said.

“The world has never seen an approach to rapid prototyping like this before. As ever, SCAD students are the earliest adopters of design technology.”