Stratasys announced that it is previewing demonstrations of next generation manufacturing technologies at IMTS 2016 as part of its SHAPING WHAT’S NEXT™ vision for manufacturing.

Image credit: Business Wire

SHAPING WHAT’S NEXT builds on the company’s industrial FDM® 3D printing expertise, helping customers to overcome the challenge of rapidly producing bigger, stronger, higher quality parts ranging in size from an automobile armrest to an entire aircraft interior panel.

The Stratasys Infinite-Build 3D Demonstrator – to be displayed at the company’s IMTS booth on 12-17 September – is designed to address the requirements of aerospace, automotive and other industries for large lightweight, thermoplastic parts with repeatable mechanical properties.

According to the company, the Infinite-Build 3D Demonstrator features a revolutionary approach to FDM extrusion that increases throughput and repeatability.

“The system turns the traditional 3D printer concept on its side to realize an “infinite-build” approach which prints on a vertical plane for practically unlimited part size in the build direction,” Statasys said in a press release.

Aerospace giant Boeing, which is currently using an Infinite-Build 3D Demonstrator to explore the production of low volume, lightweight parts, played an influential role in defining the requirements and specifications for the demonstrator.

Image credit: Business Wire

“Additive manufacturing represents a great opportunity for Boeing and our customers, so we made a strategic decision more than a decade ago to work closely with Stratasys on this technology. We are always looking for ways to reduce the cost and weight of aircraft structures, or reduce the time it takes to prototype and test new tools and products so we can provide them to customers in a more affordable and rapid manner,” said Darryl Davis, President, Boeing Phantom Works.

“The Stratasys Infinite-Build 3D Demonstrator enables products to be made at a much larger and potentially unlimited length, offering us a breakthrough tool to add to our robust additive manufacturing processes.”

Ford is also exploring innovative automotive manufacturing applications for this demonstrator, and the two companies will work together to test and develop new applications for automotive-grade 3D printed materials that were not previously possible due to limited size.

“3D printing holds the promise of changing automotive design and manufacturing because it opens up new ways to innovate and create efficiencies in production,” said Mike Whitens, director, Vehicle Enterprise Sciences, Ford Research & Advanced Engineering.

“Our vision at Ford is to make high-speed, high-quality printing of automotive-grade parts a reality. We are excited about the future opportunities that the scalable and versatile Infinite-Build concept can unlock, and look forward to collaborating with Stratasys to help achieve our goals.”

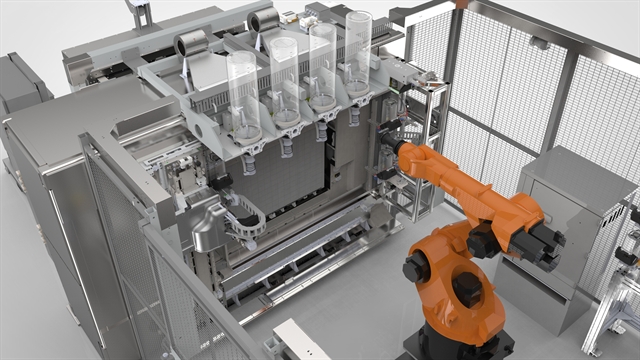

Stratasys has also been working closely with Siemens to advance their shared vision of making 3D printing a viable and indispensable component of production manufacturing.

The collaboration has led to the development of the Robotic Composite 3D Demonstrator integrating Statasys’ core additive manufacturing technologies with industrial motion control hardware and design-to-3D printing software capabilities provided by Siemens.

“Siemens is pleased to support Stratasys in their innovative additive manufacturing initiatives, of which the Stratasys Robotic Composite 3D Demonstrator is one of the most promising,” said Arun Jain, VP, Motion Control, Digital Factory US, Siemens.

“By working closely with Stratasys on motion control and CNC automation, Siemens is helping to create a flexible, multi-function manufacturing workflow that puts 3D printing firmly in the factory. We look forward to continuing to work with Stratasys to build manufacturing solutions that transform industries,”

In addition to showcasing the Infinite-Build and Robotic Composite 3D Demonstrators at IMTS 2016, Stratasys will also present examples of 3D printing applications used by its customers around the globe for tooling and manufacturing processes, including 3D printed Jigs & Fixtures, Composite Tooling, Mold Tooling and Production Parts.