Markforged has ventured into a partnership with recreational vehicles manufacturer Apollo Motorhome Holidays to integrate Markforged 3D printers into Apollo’s manufacturing process.

Apollo, which offers high-quality, luxury motorhomes, campervans, and caravans to customers globally, will use Markforged 3D printers to level up its craftsmanship and take a significant step towards revolutionising the caravan industry.

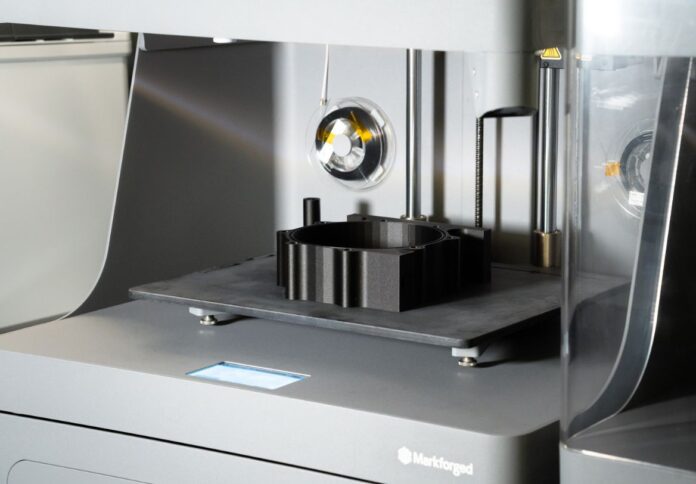

Markforged 3D printers are designed to manufacture functional, high-strength parts using a range of materials, such as carbon fibre, stainless steel, and Onyx.

In a bid to address material shortages that added delays to production, Apollo began printing small components and connectors using the X7 carbon fibre 3D printer. The company has discovered more uses for the printer, including new tools they could make and iterate to ease and accelerate the process of building RVs.

Edney Ferreira, engineering manager at Apollo, said the addition of Markforged 3D printing technology will streamline Apollo’s production and provide the company with the ability to create high-quality, custom parts that are essential to the production of its Motorhomes, Campervans and Caravans.

Powered by Markforged, Apollo is also now able to print miniatures of caravan chassis and motorhome cabinetry to show the concepts before starting the final stage of design. These miniatures can also be used to test lean concepts in an assembly line.

The RV manufacturer also plans to use the miniatures to simulate concepts for training new assembly workers, as well as print spare parts on demand for their rental business.

Slated to attend the Australian Manufacturing Week from 9 to 12 May as the sponsor of the additive manufacturing zone, Markforged will showcase its industrial 3D printers, including its FX20 printer and a host of metal binder jetting parts.

Furthermore, Richard Elving, Markforged’s senior director for Asia Pacific, will take the main stage on the first day of the event to discuss “How Australian businesses use 3D printing to re-shore manufacturing.”