A new state-of-the-art manufacturing lab, valued at $3 million, is set to be built by Applied Robotics at TAFE Queensland, powered by cutting-edge technologies from Rockwell Automation.

The project, funded by the Queensland Government’s $100 million Equipping TAFE for Our Future program, aims to train the next generation of engineers, manufacturers, and innovators.

Scheduled for installation in February 2025, the advanced lab will be located at TAFE Queensland’s Ipswich campus, Rockwell Automation said in a news release.

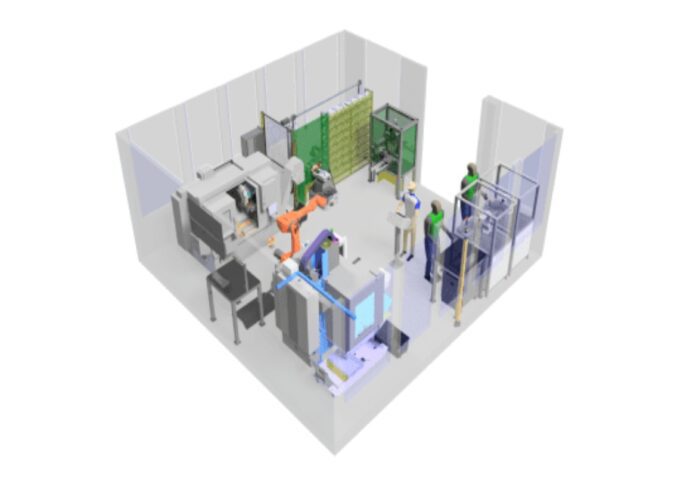

It will incorporate a range of advanced technologies from Rockwell Automation, including Internet of Things (IoT), Manufacturing Execution Systems (MES), digital twin visualisation, and Autonomous Mobile Robots (AMRs).

“We’ve had a long partnership with Rockwell, extending over 30 years. When we won the project to deliver this smart manufacturing lab, we knew Rockwell had the expertise and technologies to meet our needs,” said Isaac Roach, chief operating officer of Applied Robotics, a Silver OEM partner in Rockwell Automation’s PartnerNetwork™.

Roach highlighted Rockwell’s ability to provide a comprehensive range of technologies under one roof.

“Not many suppliers have all the technologies in one place, but with Rockwell, we could get IoT, MES, logistics technologies, PLCs, digital twin visualisation, and AMRs all from the one supplier,” he added.

The advanced manufacturing lab will focus on areas such as robotics, CNC (Computer Numerical Control) machining, machine vision and learning, as well as automated logistics and storage.

A key outcome set out by the TAFE was that we needed to be able to train the trainers, so they are well-equipped to teach students in the new lab. Rockwell was instrumental in achieving this, particularly with its Plex software running the entire system with control down to the device level,” Roach explained.

Plex, Rockwell’s SaaS-based Smart Manufacturing Platform, connects people, systems, and machines while tracking data from the shop floor to the top floor.

This system automates business processes, provides analytics, and enhances visibility and quality control.

Anthony Wong, regional director of Rockwell Automation in South Pacific, emphasised the importance of such labs in developing Australia’s future talent.

“It’s vital to nurture the next generation of manufacturing talent, and advanced labs like this will help train Australia’s innovators and entrepreneurs of the future,” Wong stated.

In addition to providing advanced automation technologies, Rockwell is also customising its solutions for an educational setting.

One example is the design of a twinned PLC system that allows students to test their programming skills on one PLC, with the option to reset to default settings if needed.

This is a really clever system for an educational setup, and Rockwell took that challenge on and delivered an ideal result,” Roach noted.

The lab will also feature Rockwell’s Emulate3D software, a digital twin technology that enables a full visualisation of plant systems.

In an educational context, students can trial their designs in a virtual environment that replicates real-world conditions, helping them fine-tune their skills without the risks of physical mistakes.

Another key component of the lab will be Rockwell’s OTTO Motors Autonomous Mobile Robots (AMRs), marking one of the first local installations of OTTO, which Rockwell acquired in 2023.

“AMRs are at the forefront of industrial automation, and OTTO Motors AMRs are known globally for enhancing productivity in manufacturing facilities. Including them in the lab was a natural choice,” Roach noted.

“People are impressed with what this partnership between industry and education is set to achieve,” Roach said.

“We are excited about these possibilities, and will look to continue to expand our strong partnership with Rockwell to continue delivering for the Australian education sector,” concluded Roach.