Rivelin Robotics has released a video showing its Netshape Robots in action in advance of the Formnext 2023 event.

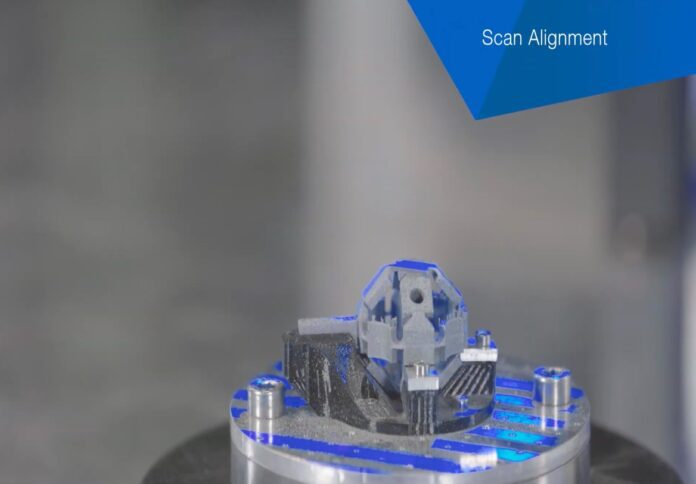

The video shows how the company’s automated metal additive manufacturing (AM) post processing technology works, and emphasises the simplicity of the solution from a user perspective.

In particular, the company specialises in the creation of several metal AM post-processing cells, including the NS0, NS1, and NS2, all of which feature robots from their partner, Yaskawa Europe, expertly controlled by Rivelin’s cutting-edge Netshape software.

The NS0 cell serves as an affordable entry point for those looking to explore and experience state-of-the-art digital manufacturing software.

Equipped with advanced Netshape control, sensing capabilities, and instructional features, it offers an ideal platform for digital manufacturing exploration.

The NS1, featured in the video, is tailored for those making the transition into full-scale production. It adeptly manages tasks such as support removal, finishing, polishing, and blasting.

With its dual finishing zones, it enhances efficiency by enabling simultaneous finishing on one side while loading and unloading on the other.

With the ability to handle parts weighing up to 600kg and dimensions of 800mm x 650mm x 600mm, the NS1 is versatile and compatible with a wide range of applications.

The NS2 takes the capabilities of the NS1 to the next level by seamlessly integrating 8 + 8 axis parallel processing.

This advanced feature harnesses the power of two robots working in harmony, enabling tasks such as inspection, handling, pick and place actions, fixturing, cleaning, and concurrent machining.

The NS2 offers unparalleled efficiency and precision, making it the preferred solution for those aiming to optimise productivity and finesse in their operations.

Rivelin CEO Robert Bush explained, “Our cells as seen in the recently released video are effectively enclosed microfactories that combine an industrial Yaskawa robot equipped with an array of tools, state-of-the-art sensors and processes to ensure dexterity and driven by the powerful NetShape® control software that we have developed.”

Bush explained that their intelligent software leverages a combination of machine learning and traditional deterministic control theory to enhance the quality and consistency of support removal and finishing.

This culminates in an automated solution for support removal and finishing, which can achieve a 90 per cent reduction in part defects, leading to substantial cost savings and the eradication of human-related risks and variations.

The company will be showcasing its innovations at the upcoming Formnext 2023 event, slated from 7 to 10 November.

Visitors can find Rivelin in Hall 12, Stand E41, where Netshape robots will be in action.

The Rivelin team will also be available to explain how their automated AM post-processing solution has the potential to address various challenges faced by metal parts manufacturers through intelligent automation.