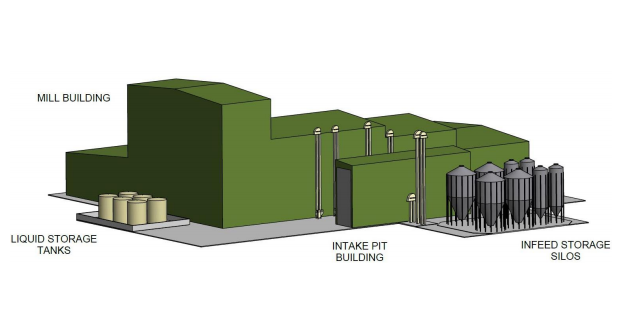

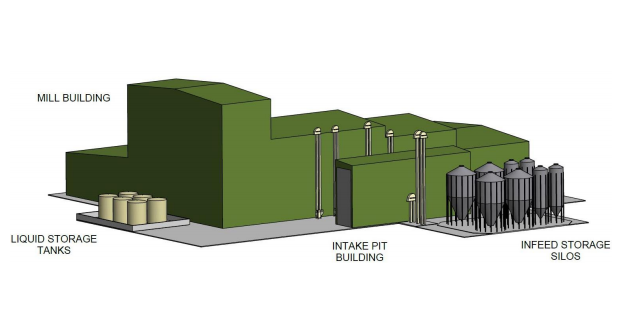

Ridley Corporation Limited has unveiled plans to construct a new state-of-the-art, fit for purpose aqua feedmill in Tasmania.

The feedmill – to be located at Westbury, just west of Launceston and south of Burnie – will manufacture and supply feed to primarily Tasmania’s Salmon Industry, as well as other aquaculture species on the mainland and in New Zealand.

Currently, the company manufactures and supplies a significant volume of aquafeed to the Tasmanian market from its Narangba facility near Brisbane, Queensland.

Ridley’s Managing Director and CEO Tim Hart said the new facility will see the company’s Tasmanian customers benefit from reduced supply chain costs, shorter delivery lead times and from being able to collaborate more closely on the product development and dietary enhancements.

He said the transfer of salmon production from Narangba to Tasmania upon commissioning of the new feedmill will be accommodated within a restructure of the Narangba operations, which will include the return of production of certain third party manufactured products, currently outsourced due to capacity constraints.

“Ridley’s commitment to a new state of the art feed mill in Tasmania supports our focus on growing with our customers, which is on the back of sustained aquaculture production growth in the region,” Mr Hart told the ASX.

“A site at Westbury has been secured and we are working hard to obtain the necessary planning approvals to support the commencement of construction in 2017.”

He said the Westbury region was chosen for its proximity to raw materials supply, with its location enabling the service of customers’ expansion much more effectively.

“The decision to expand into Tasmania reinforces the importance of the aquaculture industry to Tasmania and reflects the confidence we have in our aquafeeds team to consistently produce high quality animal nutrition solutions that are capable of outperforming competitor aquafeed in like-for-like product trials,” Mr Hart continued.

“The feedmill will provide significant local employment opportunities, not only during the period of construction but also for the mill operations and local supply chain, including opportunities for local primary producers to supply the mill with inbound raw materials.”

The new feedmill will have an annualised capacity of up to 50,000 tonnes per annum and an on-site bulk storage capacity and warehouses for both raw materials and finished goods.