A team from CU Boulder and the University of Pennsylvania has developed a 3D printing method to create materials that are elastic for heartbeats, tough for joints, and customisable for patient-specific needs.

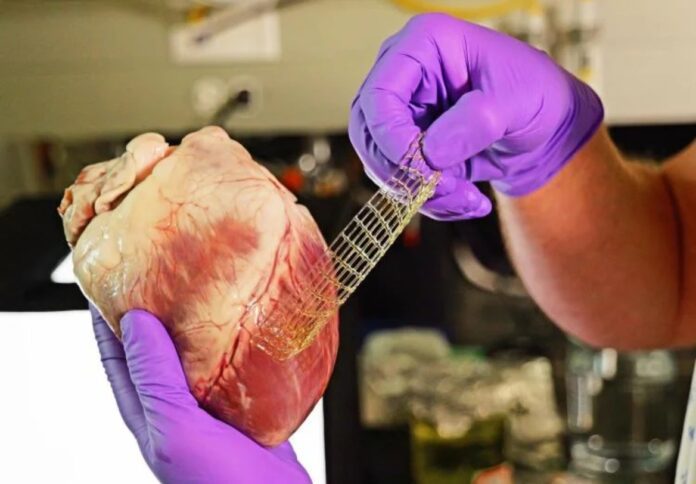

Their breakthrough, described in the 2 August edition of the journal Science, helps pave the way toward a new generation of biomaterials, from internal bandages that deliver drugs directly to the heart to cartilage patches and needle-free sutures, the university said in a news release.

“Cardiac and cartilage tissues are similar in that they have very limited capacity to repair themselves. When they’re damaged, there is no turning back,” said senior author Jason Burdick, a professor of chemical and biological engineering at CU Boulder’s BioFrontiers Institute.

He added, “By developing new, more resilient materials to enhance that repair process, we can have a big impact on patients.”

Historically, biomedical devices have been created via moulding or casting, techniques which work well for mass production of identical implants but aren’t practical when it comes to personalising those implants for specific patients.

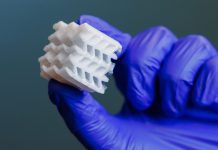

In recent years, 3D printing has opened a world of new possibilities for medical applications by allowing researchers to make materials in many shapes and structures.

Unlike typical printers, which simply place ink on paper, 3D printers deposit layer after layer of plastics, metals or even living cells to create multidimensional objects.

One specific material, known as a hydrogel (the stuff that contact lenses are made of), has been a favourite prospect for fabricating artificial tissues, organs and implants.

The university noted that getting these from the lab to the clinic has been tough because traditional 3D-printed hydrogels tend to either break when stretched, crack under pressure or are too stiff to mould around tissues.

“Imagine if you had a rigid plastic adhered to your heart. It wouldn’t deform as your heart beats,” said Burdick. “It would just fracture.”

To achieve both strength and elasticity within 3D printed hydrogels, Burdick and his colleagues took a cue from worms, which repeatedly tangle and untangle themselves around one another in three-dimensional “worm blobs” that have both solid and liquid-like properties.

Previous research has shown that incorporating similarly intertwined chains of molecules, known as “entanglements,” can make them tougher.

Their new printing method, known as CLEAR (for Continuous-curing after Light Exposure Aided by Redox initiation), follows a series of steps to entangle long molecules inside 3D-printed materials much like those intertwined worms.

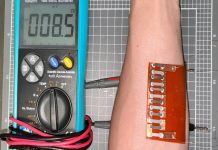

When the team stretched and weight-loaded those materials in the lab (one researcher even ran over a sample with her bike) they found them to be exponentially tougher than materials printed with a standard method of 3D printing known as Digital Light Processing (DLP). Better yet: They also conformed and stuck to animal tissues and organs.

“We can now 3D print adhesive materials that are strong enough to mechanically support tissue,” said co-first author Matt Davidson, a research associate in the Burdick Lab. “We have never been able to do that before.”

Burdick imagines a day when such 3D-printed materials could be used to repair defects in hearts, deliver tissue-regenerating drugs directly to organs or cartilage, restrain bulging discs or even stitch people up in the operating room without inflicting tissue damage like a needle and suture can.

His lab has filed for a provisional patent and plans to launch more studies soon to better understand how tissues react to the presence of such materials.

But the team stresses that their new method could have impacts far beyond medicine—in research and manufacturing too.

For instance, their method eliminates the need for additional energy to cure, or harden, parts, making the 3D printing process more environmentally friendly.

“This is a simple 3D processing method that people could ultimately use in their own academic labs as well as in industry to improve the mechanical properties of materials for a wide variety of applications,” said first author Abhishek Dhand, a researcher in the Burdick Lab and doctoral candidate in the Department of Bioengineering at the University of Pennsylvania.

“It solves a big problem for 3D printing,” he added.

Other co-authors on the paper include Hannah Zlotnick, a postdoctoral researcher in the Burdick Lab, and National Institute of Standards and Technology (NIST) scientists Thomas Kolibaba and Jason Killgore.