A group of researchers, including scientists from Argonne National Laboratory (ANL), has discovered a means to consistently manufacture 17-4 PH steel using 3D printing processes while keeping all of the material’s high-value properties.

Due to its highly durable and corrosion-resistant characteristics, manufacturers often rely on this particular type of stainless steel known as 17-4 PH to produce industrial machinery, maritime vessels, aircraft, and medical devices, as revealed in a media release by ANL.

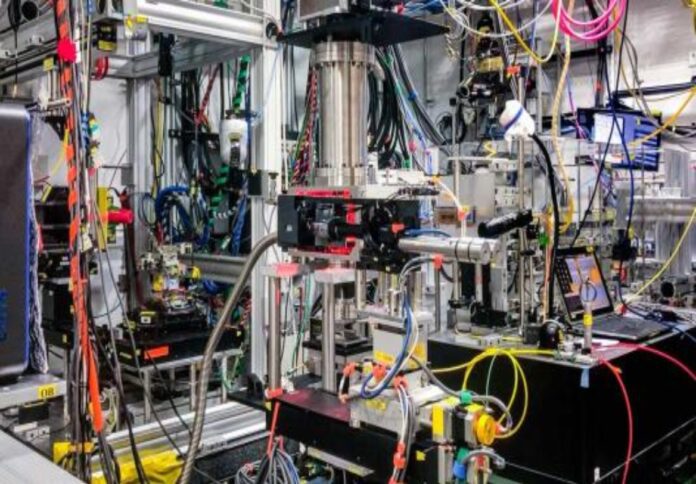

To accomplish this breakthrough, the scientists turned to the Advanced Photon Source (APS), a US Department of Energy (DOE) Office of Science user facility at DOE’s ANL.

Using a method called X-ray diffraction, scientists from Argonne, the National Institute of Standards and Technology (NIST), and the University of Wisconsin-Madison were able to study the subtle, quick phase shifts of materials as the steel was being printed.

This made it possible for them to keep an eye on, guide, and evaluate the development of its structure.

Argonne detailed that the crystal structure of 17-4 PH steel needs to be precisely composed when 3D printing.

Precipitation hardening, also known as PH, is a heat treatment method used to strengthen malleable materials, and the figures in the PH stand for the alloy’s composition: 17 per cent chromium and four per cent nickel.

Nanoparticles are also part of the 17-4 PH steel’s structure and they help to provide the material’s distinctive strength.

“When a material cools very fast during 3D printing the way 17-4 PH steel does, manufacturers previously struggled to understand it well and couldn’t predict what they were going to get,” said Lianyi Chen, an associate professor in the Mechanical Engineering department at the University of Wisconsin–Madison, who was part of the research team. ?

Chen added that even in fast-cooling conditions, the APS was crucial in enabling the team to observe the material’s transformation behaviour, pointing out that researchers were able to examine the structure in real-time to see how it changes.

Using the high-energy X-ray beams that the APS produces, ?“We can now actually look inside the metal as it’s being made to observe phase formation sequences. These have a significant impact on the final properties of the steels,” said Andrew Chihpin Chuang, a physicist in the X-ray Science division at Argonne.

Meanwhile, according to Peter Kenesei, a physicist in Argonne’s X-ray Science division, researchers can make quick judgments to alter the printing parameters to get the desired microstructure.

The researchers believe their findings demonstrate how user facilities like the APS may give the US a competitive advantage in bringing forward the next generation of advanced manufacturing technologies.

“We hope our success with this study helps increase the industrial impact of the research coming out of American synchrotron user facilities such as the APS,” said researcher Fan Zhang, a physicist at NIST. ?