Researchers at UNSW Sydney have pioneered a groundbreaking low-energy technique for recycling plastic, poised to revolutionise the recycling landscape and potentially transform everyday products like Tim Tams.

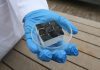

In a news release, scientists said the innovative process can convert various forms of plastic waste into polymer nanoparticles dispersed in water.

These nanoparticles can then be extracted for reuse in producing new consumer goods or utilised in their aqueous form for applications like asphalting and waterproof coatings.

Importantly, the method also removes dyes from the original plastic waste, streamlining the recycling process and expanding the sources of recyclable materials.

Headed by Professor Per Zetterlund and Dr Vipul Agarwal from the School of Chemical Engineering, the UNSW team has partnered with ‘impact investment’ firm FP Paradigm to further develop and commercialise the technology, particularly focusing on PET (polyethylene terephthalate) recycling.

A recent deal between Paco Industries, a subcontractor for FP Paradigm, and the renowned Arnott’s Group has opened doors for the implementation of this innovative technology in the production of PET alternatives for Arnott’s products, including Tim Tams and Shapes.

Dr Agarwal emphasised the significance of this breakthrough, particularly in the context of Australia’s plastic recycling challenges, where a vast majority of plastic ends up in landfills due to limitations in existing recycling methods.

“The other advantages of this new technology are tolerance to mixed plastic waste allowing segregation of different waste plastics during the recycling process, and recycling of chemicals used in the process,” said Dr Agarwal.

He continued, “Our method has the potential of causing no mechanical or chemical degradation of the polymer, so we believe it may be possible to recycle the plastic a higher number of times than using existing recycling processes.”

“In addition, there is no need for extensive cleaning of the waste plastic before it is recycled. This process also has the potential to separate the polymer from various additives such as dyes, eliminating one of the stages currently required in current recycling processes.”

Meanwhile, Prof Zetterlund highlighted the key advantages of their method, including the absence of mechanical or chemical degradation of the polymer during recycling, thus potentially allowing for multiple recycling cycles without compromising the quality of the material.

Moreover, the technology offers benefits such as segregation of different plastic types during recycling and the potential to recover chemicals used in the process, further enhancing its sustainability.

In addition to its application in food and beverage packaging, the aqueous dispersion of plastic polymer nanoparticles holds promise for a range of other uses, including in asphalt production, paints, and insulation coatings, presenting a versatile and sustainable solution to plastic waste.