Researchers at Georgia Institute of Technology have pioneered a novel 3D printing technique for crafting small glass structures, lenses, and more, using ultraviolet (UV) light instead of the conventional high-temperature methods.

This innovation opens new possibilities for creating glass components essential for medical devices, microelectronics, and various research applications, Georgia Tech said in a news release.

Traditionally, converting printed polymer resin into silica glass required extreme temperatures of around 1,100 degrees Celsius and lengthy curing times exceeding half a day.

However, the Georgia Tech team, led by Professor H. Jerry Qi from the George W. Woodruff School of Mechanical Engineering, has drastically reduced both the temperature and curing time.

“This is one of the exploratory examples showing that it is possible to fabricate ceramics at mild conditions because silica is a kind of ceramic,” Qi said.

Their new process operates at approximately 220 degrees Celsius and takes just five hours.

This discovery not only enables the production of glass microstructures, including miniature lenses suitable for medical imaging within the human body but also holds promise for microfluidic devices.

These microfluidics, akin to small computer chips with nano- or microscale channels, are employed in the study of cells and biofluids in motion.

Glass-based microfluidics offer distinct advantages over polymer-based counterparts, as they are more resistant to chemical corrosion and body fluids.

Furthermore, the low-temperature 3D printing process could revolutionise microelectronics manufacturing, according to researchers.

“Semiconductor materials used in microelectronics cannot withstand very high temperatures. If we want to print directly on a board, we have to do it at a low temperature, and 200 degrees C can definitely do this job,” explained Mingzhe Li, the study’s first author.

Traditional glass additive manufacturing techniques often involve polymer mixtures that must be burned away with high heat after shaping.

In contrast, the Georgia Tech approach utilises a light-sensitive resin based on a widely used soft polymer known as PDMS.

The conversion to glass is achieved using deep UV light, eliminating the need for extreme temperatures and conserving energy.

Moreover, this method avoids the addition of silica nanoparticles, resulting in highly transparent glass with no associated optical issues.

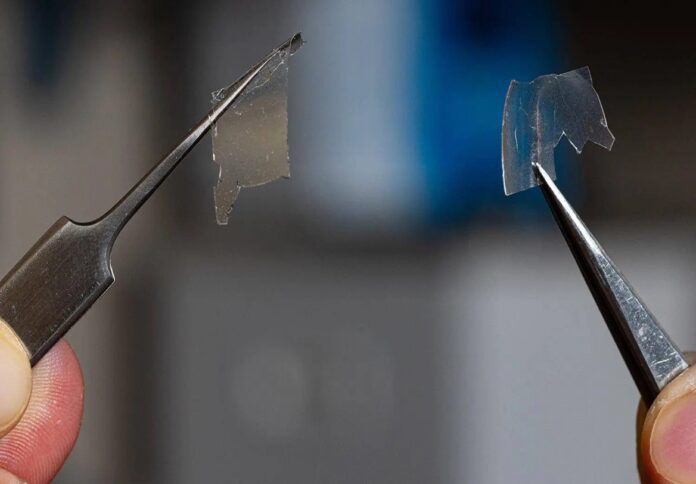

The glass lenses produced through this process are as smooth as commercially made fused silica glass.

Currently, the research team’s process creates structures within the range of 200 to 300 micrometres in size, equivalent to the thickness of a sheet of paper or the diameter of a human hair.

Plans are underway to scale up glass structures to the millimetre scale.

The university said this cutting-edge development aligns with the growing interest in ceramics and advancements in 3D printing technology.

The Office of Naval Research, which recognises the potential of this approach, provided funding to support the project.