Researchers have introduced an experimental wearable device that harnesses power from a user’s finger movements and possesses the ability to create and store memories, showing promise in the field of health monitoring and other applications.

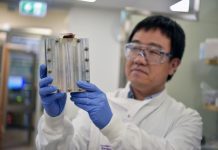

In a news release, RMIT University revealed the device integrates a single nanomaterial within a flexible casing, which is worn on the user’s finger.

This nanomaterial allows the device to generate power through the bending of the user’s finger, and the super-thin material also empowers the device to undertake memory-related tasks.

Unlike multifunctional devices that often necessitate multiple materials stacked in layers, this innovative device simplifies the process by utilising a single nanomaterial, eliminating the intricate challenge of layering nanomaterials precisely.

This technology was developed through a collaboration led by RMIT University and the University of Melbourne, in conjunction with various Australian and international institutions.

The device’s core material comprises the rust of a low-temperature liquid metal known as bismuth, selected for its safety and compatibility with wearable applications.

Dr Ali Zavabeti, the senior lead researcher, envisions this invention evolving into medical wearables designed to monitor vital signs, building upon the team’s prior research in gas-sensing materials and personal data storage.

“The innovation was used in our experiments to write, erase and re-write images in nanoscale, so it could feasibly be developed to one day encode bank notes, original art or authentication services,” said Zavabeti, an engineer from RMIT and the University of Melbourne.

In experiments, this innovative device displayed remarkable sensitivity to human movements, particularly in response to activities such as stretching, establishing its potential as a candidate for wearable technologies. The device, when attached to a finger joint, achieved an average output peak of about 1 volt.

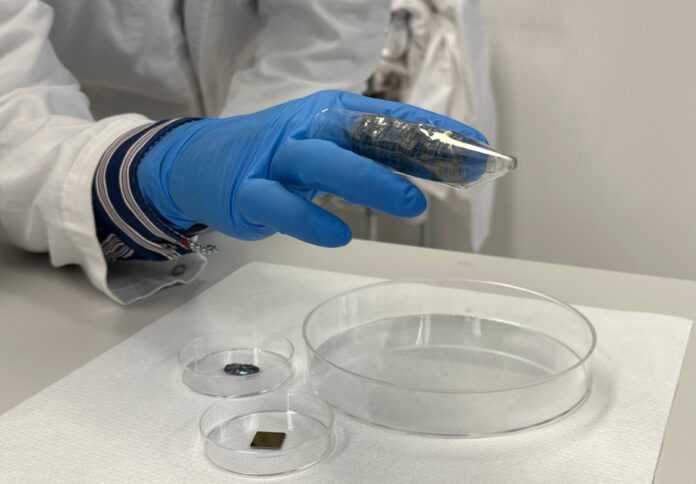

During these experiments, it produced the RMIT logo and a square-shaped insignia, all of which were stored within a space no larger than the width of a human hair.

The manufacturing process behind this invention involved printing layers of bismuth rust, also known as oxide, in a matter of seconds.

The team pioneered an instant-printing technique that utilized low-melting point liquid metals.

The nanoscale engineering of materials has paved the way for a multitude of applications, spanning from sensing and energy harvesting to memory functions.

This bismuth oxide-based material can serve as a semiconductor, enabling computational tasks. Furthermore, it acts as a nanogenerator, efficiently harnessing green energy from environmental vibrations and mechanical movements.

The device’s use of bismuth oxide is expected to be less irritating to the skin in comparison to silicon. Its durability, combined with its stretchability, makes it an ideal candidate for integration into various wearable technologies.

The research team is actively seeking collaboration with industry partners to further develop and prototype this innovative device.

They also plan to adapt their approach to the utilization of low-temperature liquid and solid metals and alloys in the creation of personalized wearables.

The research was funded by the Australian Research Council and received additional support from the National Computational Infrastructure.

The project also benefited from the resources of the Microscopy and Microanalysis Facility (RMMF) and Micro Nano Research Facility (MNRF) at RMIT, along with the Department of Chemical Engineering and Physics at the University of Melbourne.

The research team included members from the University of Toronto, Western Sydney University, University of Sydney, University of New South Wales, and the Australian National University.