Image credit: Melanie Gonick/MIT

A team of researchers from the Massachusetts Institute of Technology (MIT) has designed one of the strongest lightweight materials that is 10 times stronger than steel.

Image credit: Melanie Gonick/MIT

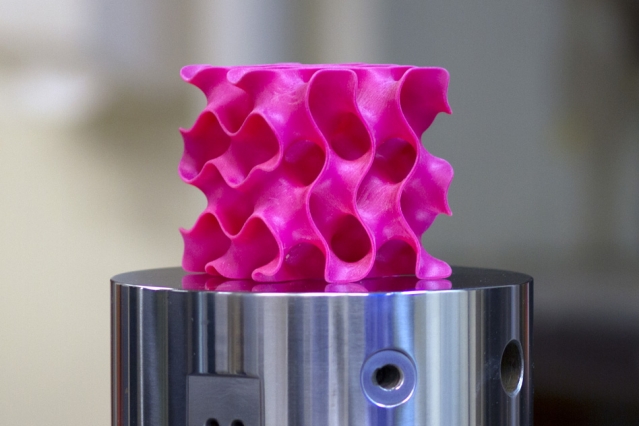

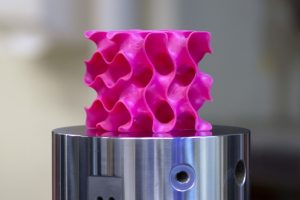

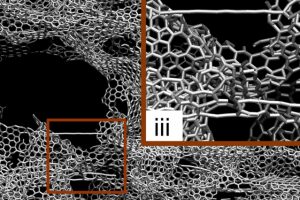

The new material – a sponge-like configuration with a density of just 5% – was developed by compressing fusing flakes of graphene, a two dimensional form of carbon.

McAfee Professor of Engineering, Zhao Qin, said this process produced a strong, stable structure whose form resembles that of some corals and microscopic creatures called diatoms. He said that these shapes – which have an enormous surface area in proportion to their volume – proved to be remarkably strong.

“Once we created these 3D structures, we wanted to see what’s the limit — what’s the strongest possible material we can produce,” Mr Qin continued.

He said the team then proceeded to create a variety of 3D models and subjected them to various tests.

“One of our samples has 5% the density of steel, but 10 times the strength,” Mr Qin noted.

The new graphene configurations have been made in the lab using a high-resolution, multimaterial 3D printer. They were mechanically tested for their tensile and compressive properties, and their mechanical response under loading was simulated using the team’s theoretical models. The results from the experiments and simulations matched accurately.

Image credit: Zhao Qin

Markus Buehler, the head of MIT’s Department of Civil and Environmental Engineering (CEE), said the new material could find a number of applications for industries that require a combination of extreme strength and light weight.

He said the new findings show that the crucial aspect of the new 3D forms has more to do with their unusual geometrical configuration than with the material itself, which suggests that similar strong, lightweight materials could be made from a variety of materials by creating similar geometric features.

“You could either use the real graphene material or use the geometry we discovered with other materials, like polymers or metals,” Mr Buehler explained.

“You can replace the material itself with anything. The geometry is the dominant factor. It’s something that has the potential to transfer to many things.”

The team believes that because the shape is riddled with very tiny pore spaces, the material might also find application in some filtration systems, for either water or chemical processing.

“This is an inspiring study on the mechanics of 3D graphene assembly,” said Huajian Gao, a professor of engineering at Brown University, who did not participate in the project.

“The combination of computational modelling with 3D printing-based experiments used in this paper is a powerful new approach in engineering research. It is impressive to see the scaling laws initially derived from nanoscale simulations resurface in macroscale experiments under the help of 3D printing.”

The research, which was published in the journal Science Advances, was supported by the Office of Naval Research, the Department of Defence Multidisciplinary University Research Initiative, and BASF-North American Centre for Research on Advanced Materials.