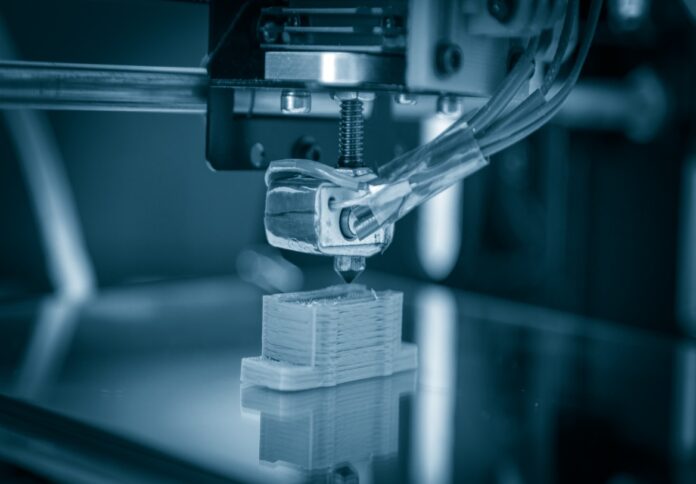

Additive manufacturing continues to revolutionise how components and tools are manufactured on a large scale. However, due to a lack of materials, lengthy print times, high cost, and strict quality criteria, 3D printing was not initially a feasible alternative for large-scale industrial manufacturing.

Even in the most demanding industrial conditions, businesses can now produce factory floor-ready components at scale rapidly and more cost-effectively without sacrificing quality thanks to recent improvements in high-performance printing machines, design software, and approved materials.

As 3D printing develops, the hype around the promises made by this technology must give way to the reality of its widespread use on factory floors today. In research commissioned by Texas-based manufacturer Essentium, 170 managers and executives – responsible for decisions regarding 3D printing for production parts – were surveyed online. Results of the independent study demonstrate how 3D printing has a positive effect on cutting carbon emissions.

3D printing and its impact on sustainability initiatives

As businesses face supply chain issues, an increasing number are turning to environmentally friendly manufacturing approaches, such as recyclable materials and decreased energy use, among others.

The Essentium-commissioned study found that 94 per cent of manufacturers are actively involved in carbon-reduction activities, with 53 per cent having mature and strategic programs in place.

According to the survey, 86 per cent of manufacturers with carbon reduction projects claim positive outcomes from this technology. Manufacturers cite numerous benefits, including reduced waste, shorter supply chains, elimination or reduction of overruns, decreased carbon footprint for parts transportation, lower overall carbon emissions, streamlined logistics requirements, and optimised storage footprints.

The report also showed that nearly all, 98 per cent of firms, believe that 3D printing is essential for their carbon reduction programs, highlighting the role that this technology plays in promoting a favourable shift in the environment.

“This research highlights the 3D printing’s capacity to manufacture products in a much more eco-friendly way,” says Nirup Nagabandi, PhD, vice president of Materials and Process Engineering at Essentium.

He added, “Specifically, we are working with customers and partners to transform the manufacturing industry by enabling efficient production methods that reduce waste, cut energy consumption and eliminate transportation emissions.”

How 3D printing aided in supply chain issues

Manufacturing is the engine that powers the local, national, and global economy. The manufacturing business has seen considerable changes in recent years, including supply chain challenges that have prompted many companies to abandon traditional production procedures in order to keep the lights on.

When manufacturing stakeholders were surveyed on how they dealt with recent supply chain challenges, 71 per cent said they used 3D printing to manufacture products.

Over half or 56 per cent of the manufacturers that tried using 3D printing to solve supply chain problems said it was a “very effective” solution. All of the manufacturers who tried using 3D printing to solve supply chain problems said it worked, 100 per cent, and that it was effective.

3D printing is projected to grow further

While 3D printing is undeniably growing in its applications throughout manufacturing, there is an obvious question of the continual pattern of usage spikes and dramatic growth year over year plateau or slow down. When manufacturing leaders were asked to quantify how their use of 3D printing will change in the next three to five years, 95 per cent expect it to increase, with 41 per cent describing that increase as “dramatic.” It is worth noting that this latter figure has remained stable over the years that we have been conducting this research.

These results indicate that there is still an opportunity for 3D printing development as the technology expands in breadth. However, all 3D printing stakeholders agree that more innovation is required to go to the next level of maturity. According to manufacturers, no single field requires innovation. Post-processing, software, materials, platforms, printers, and workforce development are the areas of 3D printing that require the biggest breakthroughs.

Manufacturers can attain these sustainable results thanks to the benefits of 3D printing. In comparison to conventional subtractive methods, businesses may cut down on material waste by utilising additive manufacturing techniques. Localised production made possible by 3D printing lessens reliance on intricate supply networks, which decreases the need for transportation and lowers overall carbon emissions.

For more information about the research, you may download the paper through this link.