Media Release

The Australian Renewable Energy Agency (ARENA) today released a report that outlines renewable energy options for all Australian industrial users of process heat.

ARENA CEO Darren Miller said the comprehensive report Renewable Energy Options for Industrial Process Heat shows there are myriad opportunities for industrial users to switch to renewable energy alternatives to provide process heat. The report considers all industries ranging from alumina and metals processing, ammonia, iron and steel, cement and lime, pulp and paper, oil and gas and food and beverage manufacturing. The report was produced by ITP Thermal in conjunction with Pitt&Sherry, Institute for Sustainable Futures and Beyond Zero Emissions.

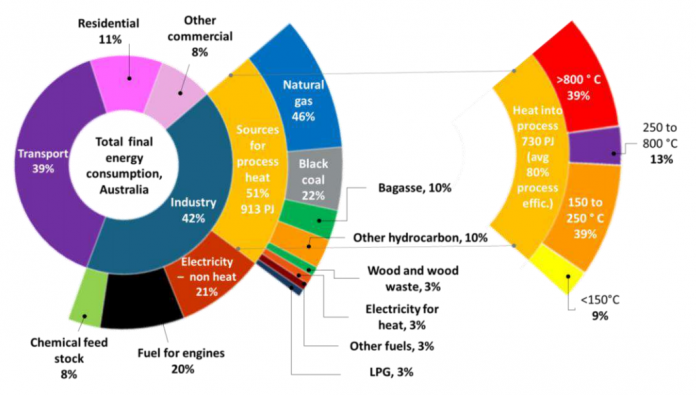

“Industry accounts for about 40 per cent of Australia’s energy use and of that, more than 50 per cent is used to produce process heat,” said Mr Miller.

“This report identifies that shifting to renewable energy to generate process heat is possible for these sites over the short, medium and long-term using numerous technologies and approaches including bioenergy, geothermal, electrification, hydrogen and solar thermal together with process redesign, combining heat and power and co-locating greenfield developments with renewable resources,” he said.

Process re-design, combined heat and power and co-locating greenfield developments to leverage off renewable resources offer potential for overall least cost solutions, the report found.

“Using renewable energy to generate process heat could displace up to 56 petajoules of gas per annum – enough to power a million average Australian homes for a year – within five years, which is significant in light of current supply conditions,” he said.

Across Australia, industrial sites that use process heat collectively use about 628 petajoules of fossil fuel heating per annum. The ITP report shows that the level of industrial experience with using renewable heat is low and barriers include a low appetite for risk and expectations of short payback times. In contrast, a key driver to increase the uptake of renewable energy is the visibility of relevant case studies.

ARENA recently launched its new Investment Plan that set supporting industry to reduce emissions as one of three investment priorities.

“Helping industry transition to renewable energy and demonstrating different ways of operating is challenging, but this report clearly shows that there are many ways to achieve emissions reduction in industry.

“ARENA can support industry to transition to renewable energy solutions and we will be engaging with large energy users to identify projects that could potentially apply for ARENA funding.

“However, we encourage everyone whose facility uses process heat in operations to download this report from our website and visit our funding page to learn how to apply.”

ARENA has previously supported a range of projects that support industry to reduce emissions through bioenergy, electrification, hybrid renewable energy solutions combining solar or wind and storage and renewable hydrogen. Recently, ARENA announced support for the Australian Alliance for Energy Productivity (A2EP) to investigate opportunities for using renewables in process heating in food and beverage manufacturing.

Image Credit: arena.gov.au