The shortage of spare parts for vintage cars has been a persistent problem for car collectors around the world, but Porsche Classic – the division of Porsche dedicated to classic vehicles – has come up with an elegant solution to this problem.

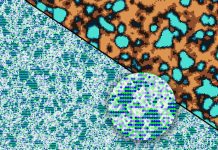

The company has announced that it has begun producing extremely rare parts for the Porsche Classic range that are only needed in small quantities using 3D printers.

According to Porsche, all parts that are produced using the 3D printing process meet the requirements in terms of absolute fidelity to the original specifications – both from a technical and a visual perspective.

This novel approach, the carmaker has said, not only eliminates tool and storage costs, but also ensures the impeccable quality and function of the component.

“As the quality of “additive” manufacturing processes continues to improve with generally decreasing costs, this form of manufacturing presents an economic alternative for the production of small quantities,” Porsche in a statement.

Porsche is currently manufacturing nine parts using 3D printing, and is now in the process of determining whether 3D printing is suitable for the production of a further 20 components.

“All parts are subject to the quality requirements of the original production period as a minimum, though they usually meet higher standards,” reads the statement.

“Accuracy in terms of size and fit is ensured by performing tests with the part installed. Depending on the area of application, plastic parts made of various materials as in the original must be resistant to oils, fuels, acids and light.”