Pfizer Australia is investing AUD 150 million to upgrade its Melbourne facility into one of the country’s most advanced pharmaceutical production sites to combat antimicrobial resistance (AMR).

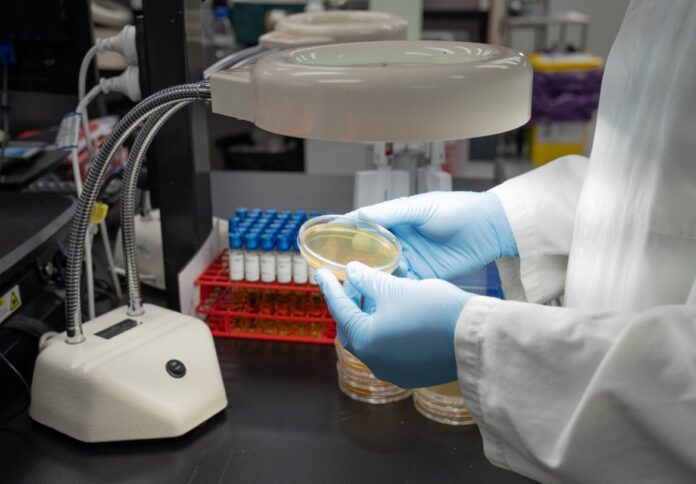

The upgrade includes the installation of cutting-edge technologies, such as robotics and AI-powered systems, to enhance the site’s specialised manufacturing capabilities, the company said in a media release.

The new facility will feature advanced freeze-drying machines known as lyophilisers, integral to the production of antimicrobial treatments.

The enhancements aim to bolster Pfizer’s ability to produce and supply critical medicines globally, reinforcing its commitment to combating AMR—a major global health threat.

Victorian Minister for Jobs and Industry Natalie Hutchins visited the site today to mark the milestone installation of these key technologies and to witness the site’s advanced capabilities.

The upgrades at the Melbourne site are expected to be completed and operational by mid-2025, with commercial manufacturing set to begin in 2026.

According to the company, AMR, often referred to as ‘the silent pandemic,’ is a growing concern as it renders infections more difficult to treat, leading to increased disease spread, severe illness, and potential death.

The World Health Organization considers AMR one of the top ten public health threats, with projections indicating that drug-resistant infections could result in 10,000 deaths annually in Australia by 2050.

“We are thrilled to reach this important milestone in our investment to support the development and delivery of new antimicrobials at our Melbourne site, and to be investing in Australia’s advanced manufacturing capabilities,” said Anne Harris, Pfizer Australia & New Zealand Managing Director.

She continued, “A key strategic pillar of Pfizer’s product innovation work is our effort to help slow the spread of antimicrobial resistance, one of the biggest global health threats of our time. We are also pleased to be providing 500 advanced manufacturing jobs at our Melbourne site.”

Currently, the Melbourne facility produces a range of medicines, including treatments for cancer, antimicrobials, anaesthetics, anti-inflammatory drugs, and more.

These medicines are exported to over 60 countries and serve up to 15 million patients annually.