A new software algorithm developed by Oak Ridge National Laboratory (ORNL) has reduced inspection times for 3D-printed parts used in nuclear applications by 85 percent.

Researchers are now adapting the algorithm for use at Idaho National Laboratory (INL) to inspect irradiated materials and nuclear fuel, marking an advancement in nuclear safety and efficiency, as revealed in a media release.

The government reported that additive manufacturing, or 3D printing, is gaining traction for fabricating complex nuclear components domestically and quickly.

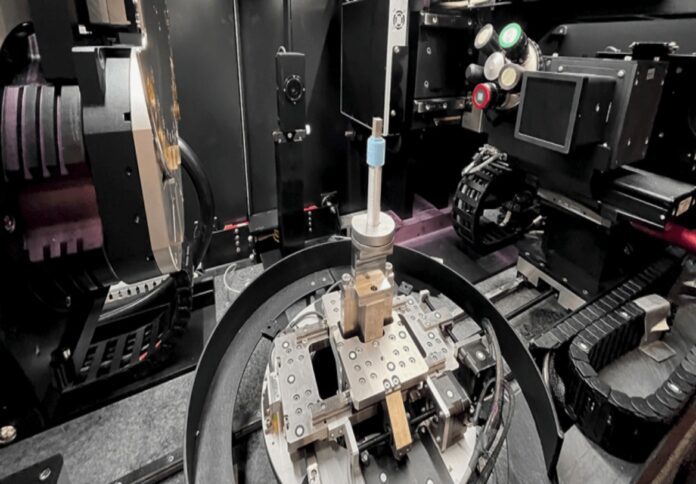

Quality assurance for these parts often involves computed tomography (CT) scans, which utilise X-rays to capture detailed images, ensuring the internal structures are free from defects.

ORNL’s new machine-learning-based algorithm enhances this process by rapidly reconstructing and analysing CT images.

Applying the algorithm, INL researchers were able to analyse over 30 3D-printed samples in under five hours—an inspection that previously would have taken more than 30 hours without the software.

At INL, researchers often delay examining materials from nuclear reactors to prioritise lab technicians’ safety, as prolonged CT scans of irradiated materials expose both personnel and equipment to radiation.

Extended exposure can degrade the CT detector, limiting its operational life and image accuracy.

By shortening scan times, the new algorithm lowers radiation exposure for lab staff and equipment alike, leading to higher-quality data and more efficient feedback for performance models.

“If we use this algorithm to reduce the scan time for radioactive materials and fuels, it will increase worker safety and the rate at which we can evaluate new materials,” said Bill Chuirazzi, instrument scientist and leader of INL’s Diffraction and Imaging group.

“Down the road, it enables us to expedite the life cycle of new nuclear ideas from conception to implementation in the power grid.”

The collaboration between ORNL and INL aims to support the development and deployment of new reactor designs, crucial for decarbonising the energy sector.

ORNL researcher Amir Ziabari, who initially created the algorithm to streamline scans of 3D-printed metal parts, is now refining it to handle radioactive materials and nuclear fuels.

This algorithm development is backed by the US Department of Energy’s Advanced Materials and Manufacturing Technologies (AMMT) program, which aims to accelerate the commercialisation of innovative materials and manufacturing methods.