Advanced technology manufacturer SPEE3D has partnered with New South Wales-based Nupress to evaluate and supply applications to the Amphibious Aircraft project with a production service that grants local manufacturers access to the WarpSPEE3D metal 3D printer.

SPEE3D announced last December that Nupress would host a WarpSPEE3D at its Australian headquarters as part of a cooperation to make the technology available to manufacturers and enterprises through a subscription rather than having to lease or buy it.

The manufacturing of applications needed for the Amphibious Aircraft project using SPEE3D’s WarpSPEE3D technology will be done in collaboration with Amphibian Aerospace, according to a recent announcement from Nupress.

This collaboration’s main goal is to assess the manufacturing process necessary to produce compliant amphibious aircraft parts utilising SPEE3D’s innovative manufacturing process as an alternative to conventional casting techniques that rely on wrought material.

“Our collaboration with Nupress and SPEE3D stands to be a game changer in aerospace manufacturing and a real opportunity for a new era of Australian manufacturing,” said Dan Webster, CEO of Amphibian Aerospace Industries Pty Ltd.

The WarpSPEE3D at Nupress is part of a partnership with SPEE3D to provide Nupress clients and other organisations with an accessible subscription-based metal 3D printing service for medium to long-term projects.

SPEE3D said the subscription will provide the local area and beyond with a revolutionary chance to acquire industrial metal part replacements created when needed.

“The performance of a machined part and a 3D printed part can be greatly different, depending on the application. Our project with Amphibian Aerospace will compare these two types of parts so that we can better understand the performance differences between them,” said Craig McWilliam, CEO of Nupress.

“We will be taking a cast part as our baseline and then creating identical machined and 3D printed versions of it. By comparing these parts on performance metrics like strength, flexibility, and weight, we should be able to see exactly how machining and 3D printing technologies are changing the landscape of functional parts,” McWilliam continued.

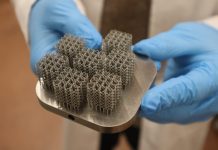

The WarpSPEE3D is capable of producing numerous pieces at once up to 40 kg at quick build rates of 100g per minute and is compatible with 12 various metals, including aluminium 6061, aluminium bronze, copper, and stainless steel.

This indicates that metal pieces can be fabricated in a matter of minutes or hours, according to SPEE3D.

“Having a WarpSPEE3D at Nupress will provide clients a critical advantage to source industrial-grade metal parts when needed, allowing them to control the production process compared to dealing with global supply chains fraught with risk,” said Byron Kennedy, SPEE3D CEO.

The metal 3D printing subscription model now available at Nupress is offering one to six slots, each delivering 25 hours per month of printing for 12 months.