Independent research centre SRI International has developed a new process for producing titanium, which is significantly cheaper and less energy-intensive than all existing techniques.

Image credit: flick user: Oak Ridge National Laboratory

While the conventional method for producing titanium, called the Kroll process, takes significant amount of energy and multiple steps requiring very high temperatures to deliver the product, the new process takes fewer steps, uses less energy, and produces titanium powder, rather than ingots.

The powder is then pressed and fused into something that’s very close to the shape of the final product, which reduces the amount of machining required.

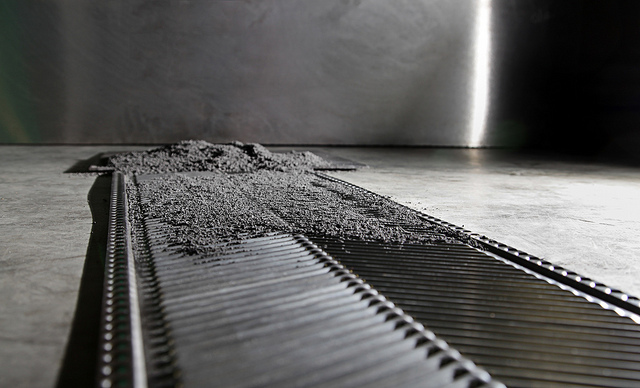

According to Technology Review, SRI’s new method uses plasma arcs to facilitate reactions between molecules of hydrogen and titanium chloride, a chemical produced from titanium ore. The reactions produce titanium vapour that quickly solidifies and forms titanium powder.

“Arcs, like lightning bolts, crack the hydrogen, producing atomic hydrogen that can readily react,” says Barbara Heydorn, senior director of the Energy Centre at SRI.

Titanium is a metal which is increasingly used in aircrafts to reduce weight and fuel consumption. Volatile fuel prices, carbon emissions limits in Europe and the prospect of introducing similar regulations in the United States are also boosting the use of titanium in planes. It also serves as a critical structural material in newer aircrafts that use carbon composite materials, since the aluminium ordinarily used in aircraft structures is incompatible with carbon composites.

The company hopes the new technique could lead to titanium being used to reduce the weight of cars, helping automakers meet tightening fuel economy regulations. Its lightweight and corrosion-resistant properties make it ideal for manufacturing certain engine parts, including fan blades.

SRI International has thus far demonstrated a small-scale version of its newly developed technique for producing pure titanium. The company is currently working on a two-scale process to improve yields and lower costs before it proceeds to scale up the process.

Donald Sadoway, a Professor of Materials Chemistry at MIT, says SRI could face major challenges to bring the new process to the market. He says introducing a new metals process is particularly difficult, as it requires large investments to make cost-efficient processing plants. According to him, the company will likely find it hard to get funding for new technologies because they could face “the widely held belief that the metals industry is mature and that the optimum processes have been discovered.”