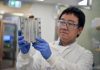

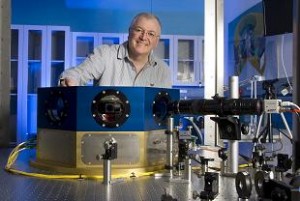

Australia’s first metrological scanning probe microscope (mSPM) is now in operation at the National Measurement Institute (NMI) in Sydney.

The NMI is the Government body responsible for maintaining the units and standards of measurement in Australia.

The microscope, which would serve as Australia’s primary standard for nanoscale length measurement, was launched on Wednesday. Its launching marks the culmination of a five-year effort to design and build an instrument which could measure materials and structures that are a million times smaller than a grain of sand.

Minister for Innovation, Industry, Science and Research, Senator Kim Carr said although the mSPM measures minute objects, it offers huge benefits for Australian businesses.

“Australian businesses wanting to compete in global markets, especially in the growing Asian market, will now have access to this leading-edge instrument,” said Mr. Carr in a media release.

“Nanotechnology is rapidly developing and finding more and more real-life applications: think targeted drug delivery, coatings for energy efficient buildings, and lighter and longer- lasting batteries.”

According to NMI the instrument establishes a direct link between the SI unit of length, the meter and practical nanoscale length measurements, which will consequently give Australian industries and researchers the confidence to make decisions when nanoscale accuracy is of utmost importance.

On Wednesday Minister Carr also addressed an audience at the groundbreaking of the Australian Institute of Nanoscience wherein he said nanotechnology has a huge potential for the next generation of products in Australian manufacturing.

“The great potential of nanoscience was already abundantly clear to me,” said Mr. Carr in his speech.

“We were seeing sensors to make workplaces safer. New treatments for disease, including cancer and AIDS. New clean energy solutions, from solar cells to carbon storage.”

The world market for nanotechnology products is estimated to be at US$ 3 trillion by 2020, with six million new workers around the world.

The mSPM’s design follows metrological principles to achieve accurate position measurement. The technology minimizes uncertainty contributions from deformation of the frame, alignment errors and effects of environmental fluctuations says scientists from the NMI.

The mSPM was built according to extremely exacting specifications by the NMI. Measurements are comparable with similar measurements made anywhere in the world.