Researchers from Flinders University and German biomaterials developer one • five have designed new biopolymer coating materials that would address packaging waste issues in the fast-food industry.

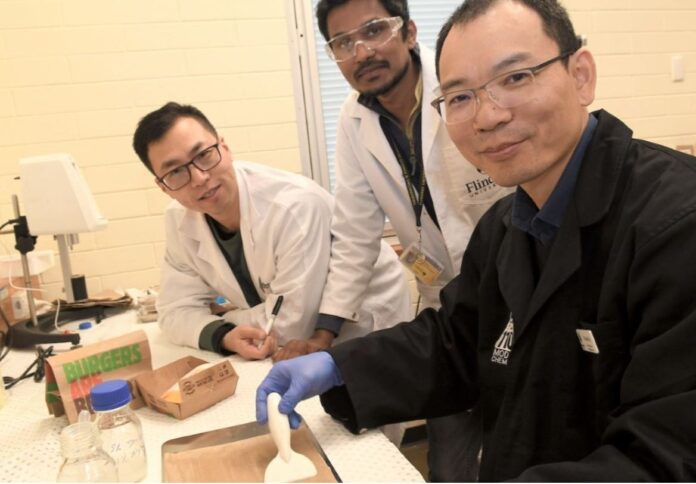

Led by Zhongfan Jia, a lead researcher from the Flinders Institute for Nanoscale Science and Technology and research colleague Peng Su in association with the Flinders Centre for Marine Bioproducts Development, the research team used seaweed extracts to develop a new non-pollutive material to replace conventional fossil-based plastic coatings used in grease-resistant fast-food packaging.

The new prototype coating meets the functional requirements of conventional grease-resistant packaging materials while also presenting an environmentally circular solution, Flinders University said in a statement.

Claire Gusko, one of one • five’s co-founders, said the next-generation material could reduce harmful plastic pollution, with feedstock also being used to achieve environmentally regenerative properties.

“Seaweed cultivation helps to naturally rehabilitate marine environments, reduce greenhouse gases, and mitigate coastal erosion. It’s important for us to use sustainable inputs upstream to ensure our products are environmentally safe, from cradle to grave,” Gusko added.

Biomass for the new coating formulation is made from natural polymers extracted from seaweeds that are native to the South Australian coastline. This is one of the primary reasons why Flinders University researchers studied the species for more broad scientific applications.

The extracts were a result of a proprietary processing methodology, creating functional biopolymer sheets that can be cut or coated onto various surfaces, depending on the applications.

“The seaweed extracts have a similar structure to the natural fibres from which paper is made,” says Dr Jia. “Our novel specialist treatments boost the grease-resistance feature of the seaweed via simple modifications while not affecting biodegradability nor recyclability of the coated paper.”

Flinders and one • five are now working on bringing laboratory-scale processing of the biopolymer coating to industrial-scale manufacturing.