An Australian high-tech spinout from Swinburne University of Technology is poised to enhance the country’s advanced manufacturing sector by delivering high-performance High Entropy Material (HEM) powders.

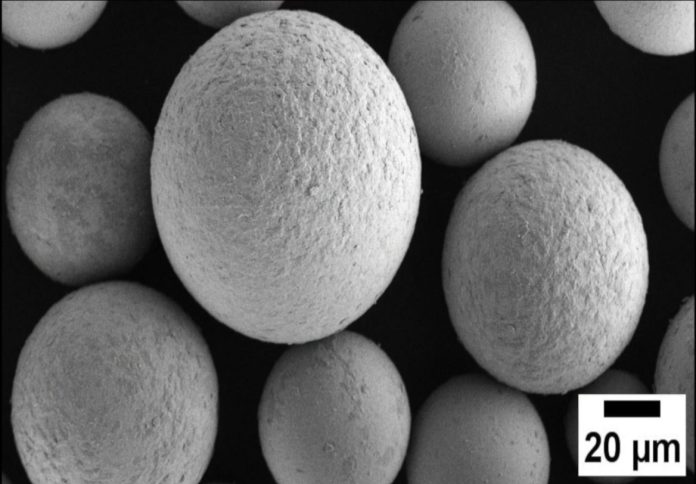

Developed from recycled industrial feedstocks, these Australian-made powders will be supplied to advanced manufacturing and 3D printing facilities, Swinburne said in a news release.

Swinburne, in partnership with Breakthrough Victoria’s University Innovation Platform, is funding EntroMat, a company commercialising HEMs.

These engineered alloys are designed for extreme performance and sustainability, combining multiple principal elements to create next-generation materials with superior mechanical strength, thermal stability, and resistance to corrosion, wear, and radiation.

EntroMat aims to redefine advanced alloy development by integrating computational alloy design, circular use of critical minerals, and scalable powder manufacturing.

This initiative is expected to bolster Australia’s sovereign capability in high-performance materials development, benefiting industries such as aerospace, mining, energy, defence, and medical technology.

Greg Lindsay, CEO of EntroMat and Swinburne’s Founder in Residence, highlighted the impact of the company’s innovations on local manufacturing.

“EntroMat is built on sovereign technology developed at Swinburne over the past decade. It will create advanced materials that will outperform conventional products, creating new markets and new possibilities,” he said.

The company has already attracted interest from industry players. D&T Hydraulics, a remanufacturing service provider for the mining sector, has signed a Letter of Intent for EntroMat to develop and test a prototype HEM product for the remanufacture of hydraulic cylinder rods.

Associate Professor Andrew Ang, EntroMat co-founder and co-director of Swinburne’s Space Technology and Industry Institute, welcomed the opportunity for collaboration.

“We look forward to embarking on the journey with Australian and international industry partners that are keen on adopting these next-generation, sustainable Australian-made metal powders,” he said.

Swinburne’s Vice-President of Innovation and Enterprise, Dr Werner van der Merwe, emphasised the importance of partnerships in commercialising research breakthroughs.

“This investment is accelerating the pathway between research and commercial success. With vital early-stage funding for deep tech startups like EntroMat, we ensure strong research can create benefit industries at scale, sooner,” he said.

The initiative has also received support from the Victorian Government. Victorian Minister for Economic Growth and Jobs, Danny Pearson, stated, “The Allan Labor Government is proud to be supporting businesses through commercialisation, supporting industries and creating more highly skilled jobs.”

Breakthrough Victoria CEO Rod Bristow described EntroMat’s technology as a significant advancement for industries requiring stronger and more resilient materials.

“Our investment through the Breakthrough Victoria University Innovation Platform reflects our commitment to turning cutting-edge research into real-world solutions that drive innovation and economic growth. We’re excited to support EntroMat on their journey to revolutionise advanced manufacturing,” he said.