It was just recently that NASA successfully finished testing a rocket engine injector made entirely through 3D printing, now the space agency is taking additive manufacturing another step further with its move to take an entire 3D printer into space.

NASA and its co-designer Made in Space is building the first 3D printer for space and it is expected to be delivered to the International Space Station (ISS) in Fall 2014.

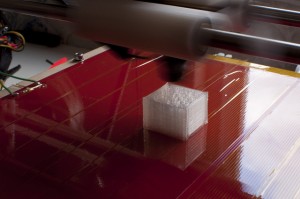

The 3D printer which is about the size of a shoe-box will be made specifically to work in micro-gravitational conditions, according to Gizmodo. The design consists of a printer fully enclosed by a casing with a glass window on the front.

The project, which is under contract with NASA’s Marshall Space Flight Center (MSFC,) is called 3D Printing in Zero-G Experiment and hopes to provide useful scientific foundation for the future of additive manufacturing in space. The printer will allow astronauts on board the ISS to print components, tools and equipment on demand in space.

“The printer is built specifically to handle the environmental challenges of space and uses extrusion additive manufacturing, which builds objects layer by layer out of polymers and other materials,” said Made in Space, via an article in Dezeen.

According to Dezeen the printer will be capable of printing 30% of the spare parts on the ISS as well as tools, specialty objects and upgrades. It will also be used to manufacture useful items such as clips, buckles and containers, all on demand.

The 3D printer will also serve as a risk reduction and feedback development mechanism for the production version of the entire Additive Manufacturing Facility (AMF) which will be flown on 2015 and will enable multiple entities to print parts in space.