ElectraLith, a start-up spun out of Monash University, is developing technology that promises to dramatically increase the efficiency of lithium manufacturing, a critical mineral for battery technologies used in electric vehicles and renewable energy storage.

According to research from Laureate Professor Huanting Wang of Monash University, ElectraLith’s technology offers a “cleaner, cheaper, faster” way of filtering lithium from salt lakes, mine tailings, and other brine solutions, including possible new sources.

Researchers said small amounts of solar electricity are all that are needed for the extraction process using ElectraLith’s innovative membrane; no additional chemicals or water are needed.

It is envisioned that the technique would assist in significantly improving the efficiency of lithium manufacturing to satisfy demand, which is expected to rise by up to 800 per cent by 2050 from the renewable energy industry alone.

With the ability to lower lithium production costs by up to 40 per cent and the lowest energy requirement and environmental impact of any method for refining lithium, ElectraLith’s innovative membrane technology also has the potential to increase onshore processing’s competitiveness.

“Current lithium extraction methods involve either roasting hard rock at high temperature and dissolving it with hot sulfuric acid, or evaporating brines in a solar pond, both of which use chemicals to precipitate lithium out,” said Professor Huanting Wang, director of the ARC Research Hub for Energy-efficient Separation at Monash University.

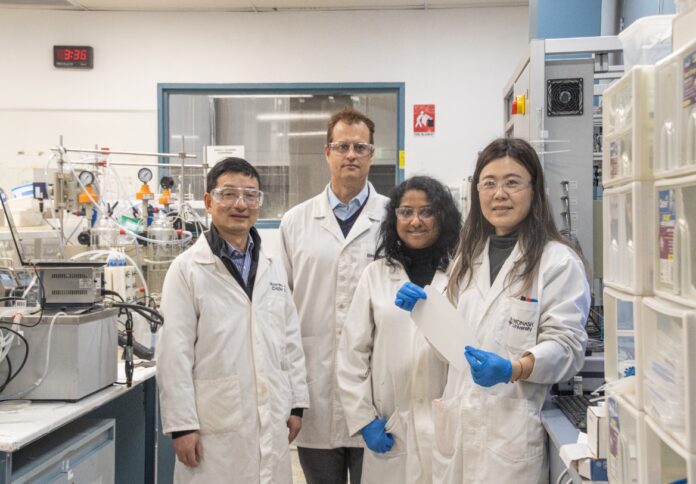

Dr Zhouyou (Emily) Wang of Monash Engineering has been given an Early Career Industry Fellowship by the Australian Research Council (ARC) in order to further develop and market the innovative membrane-based technology that has the potential to revolutionise the lithium mining and recycling sectors.

“Even though seawater is a brine, the concentration of Lithium is too low for cost-effective extraction, but we are already thinking about designing the next generation of membranes to improve Lithium extraction, so maybe in the future we can extract Lithium from new sources,” said Dr Wang.

ElectraLith’s Chief Technology Officer, Dr SJ Oosthuizen commented on the research, “ElectraLith’s team of materials scientists and electrochemists are grateful for the opportunity to discuss the company’s transformative technology at this esteemed event.”

“We are honoured to demonstrate how scientific innovation can profoundly improve how we produce, use and recycle critical minerals— all while maintaining sustainability and saving costs,” said Dr Oosthuizen.