MIT engineers have developed artificial muscle tissue capable of flexing in multiple directions, a breakthrough that could pave the way for soft, biohybrid robots with enhanced movement.

Unlike previous artificial muscles that contract in a single direction, the newly developed tissue mimics the complex patterns of natural muscle fibers, allowing for a broader range of motion.

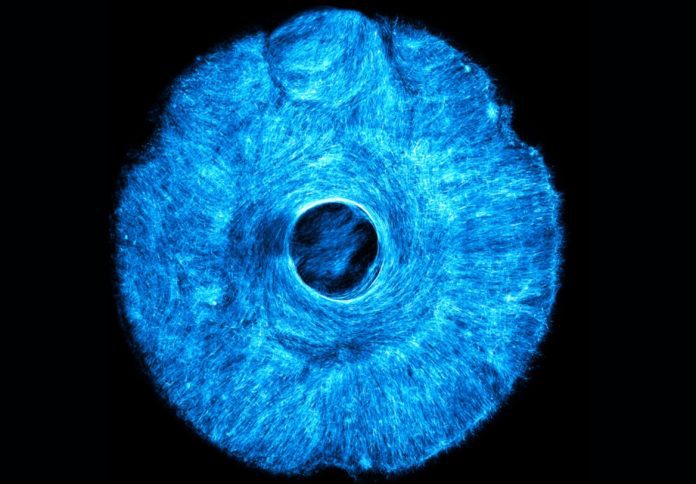

The team demonstrated their innovation by fabricating an artificial, muscle-powered structure resembling the human eye’s iris, as revealed in a university news release.

This structure contracts both concentrically and radially, mirroring the way an iris dilates and constricts the pupil.

The development was made possible through a novel “stamping” approach, which uses a 3D-printed stamp with microscopic grooves to guide muscle cell growth. When stimulated, the engineered muscle fibers contract in multiple directions based on their orientation.

“With the iris design, we believe we have demonstrated the first skeletal muscle-powered robot that generates force in more than one direction. That was uniquely enabled by this stamp approach,” said Ritu Raman, the Eugene Bell Career Development Professor of Tissue Engineering in MIT’s Department of Mechanical Engineering.

The stamp, which can be created using tabletop 3D printers, imprints patterns onto a soft hydrogel, where muscle cells are then seeded.

These cells align with the imprinted grooves, growing into structured muscle fibers. The technique offers potential applications beyond soft robotics, including in regenerative medicine, where engineered tissues could mimic the architectural complexity of natural muscle, neurons, or even heart cells.

Raman’s research, published in the journal Biomaterials Science, builds on her lab’s work in bioengineered materials.

Her team aims to develop biological structures that could restore function to individuals with neuromuscular injuries and create soft robots capable of navigating environments inaccessible to traditional machines.

“One of the cool things about natural muscle tissues is they don’t just point in one direction,” Raman said.

“Take, for instance, the circular musculature in our iris and around our trachea. And even within our arms and legs, muscle cells don’t point straight, but at an angle. Natural muscle has multiple orientations in the tissue, but we haven’t been able to replicate that in our engineered muscles.”

The research was supported by the U.S. Office of Naval Research, the U.S. Army Research Office, the U.S. National Science Foundation, and the U.S. National Institutes of Health.

Moving forward, the team intends to refine the stamping method for different cell types and explore new architectures for artificial muscle tissue.

They envision biohybrid robots that could replace rigid actuators with soft, energy-efficient alternatives, potentially offering sustainable and biodegradable solutions for underwater exploration and other applications.

Unlike previous artificial muscles that contract in a single direction, the newly developed tissue mimics the complex patterns of natural muscle fibers, allowing for a broader range of motion.

The team demonstrated their innovation by fabricating an artificial, muscle-powered structure resembling the human eye’s iris.

This structure contracts both concentrically and radially, mirroring the way an iris dilates and constricts the pupil.

The development was made possible through a novel “stamping” approach, which uses a 3D-printed stamp with microscopic grooves to guide muscle cell growth. When stimulated, the engineered muscle fibers contract in multiple directions based on their orientation.

“With the iris design, we believe we have demonstrated the first skeletal muscle-powered robot that generates force in more than one direction. That was uniquely enabled by this stamp approach,” said Ritu Raman, the Eugene Bell Career Development Professor of Tissue Engineering in MIT’s Department of Mechanical Engineering.

The stamp, which can be created using tabletop 3D printers, imprints patterns onto a soft hydrogel, where muscle cells are then seeded.

These cells align with the imprinted grooves, growing into structured muscle fibers. The technique offers potential applications beyond soft robotics, including in regenerative medicine, where engineered tissues could mimic the architectural complexity of natural muscle, neurons, or even heart cells.

Raman’s research, published in the journal Biomaterials Science, builds on her lab’s work in bioengineered materials.

Her team aims to develop biological structures that could restore function to individuals with neuromuscular injuries and create soft robots capable of navigating environments inaccessible to traditional machines.

“One of the cool things about natural muscle tissues is they don’t just point in one direction,” Raman said.

“Take, for instance, the circular musculature in our iris and around our trachea. And even within our arms and legs, muscle cells don’t point straight, but at an angle. Natural muscle has multiple orientations in the tissue, but we haven’t been able to replicate that in our engineered muscles.”

The research was supported by the U.S. Office of Naval Research, the U.S. Army Research Office, the U.S. National Science Foundation, and the U.S. National Institutes of Health.

Moving forward, the team intends to refine the stamping method for different cell types and explore new architectures for artificial muscle tissue.

They envision biohybrid robots that could replace rigid actuators with soft, energy-efficient alternatives, potentially offering sustainable and biodegradable solutions for underwater exploration and other applications.