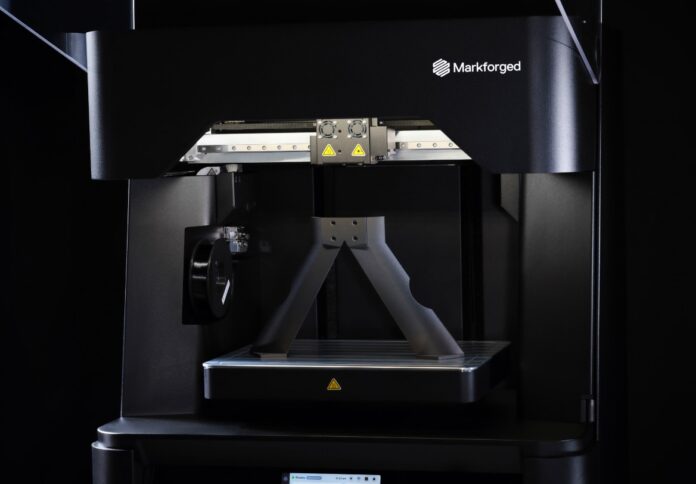

Markforged has introduced its latest industrial 3D printer, the FX10, at key manufacturing centres across Australia.

Building on the company’s reputation for high-performance printers, the FX10 is designed to enhance manufacturing line productivity and profitability, the company said in a media release.

This cutting-edge printer allows users to produce the required parts on-demand, significantly reducing costs and lead times from months to days compared to traditional manufacturing methods.

“We engineered the FX10 to be the best tool for the manufacturing floor,” said Shai Terem, CEO of Markforged.

“The FX10 allows manufacturers to slash original part replacement costs when compared to traditional methods and keep production lines running without worrying about supply chain issues or spare parts inventory,” he added.

In particular, the FX10 features modular systems designed for expansion and upgrades, including a printhead-integrated vision module that captures detailed part images and data to ensure part quality and optimise printer performance.

The 5th Generation Continuous Fiber Reinforcement (CFR) print system offers high print quality in a heated print chamber, achieving print speeds nearly twice as fast and print sizes up to twice as large as previous Markforged industrial printers.

Markforged said this capability enables the replacement of metal parts with advanced composites.

“The FX10 is another important milestone in our mission to bring industrial production to the point of need. It enables our customers to address even more industrial applications with a clear return on investment. Coupled with our Digital Source platform, we are truly starting to bring the vision of distributed manufacturing into reality,” said Terem.

The FX10 includes a suite of automation features designed to simplify printer usage and increase adoption, enhancing production resilience. When a line is down, or a tool is needed, FX10 users can simply “Press Print.”

Markforged said the printer’s user-friendly design ensures easy adoption on the manufacturing floor, starting with the first line operator.

A straightforward touchscreen interface, coupled with new automation and quality assurance technologies, allows users to produce more parts with fewer interactions needed before and during printing compared to previous models.

Markforged is showcasing the FX10 in four launch events across Australia, in Sydney, Newcastle, Brisbane, and Melbourne, with CEO Shai Terem leading the presentations.

For more information and to register for the launch events, visit the registration page.