Lockheed Martin has ventured into a research partnership with Sintavia to further study metal additive manufacturing (AM) opportunities as an alternative to castings and forgings.

Sintavia is an AM supplier to Lockheed Martin and supports several programs in the manufacture and production of metal additive parts.

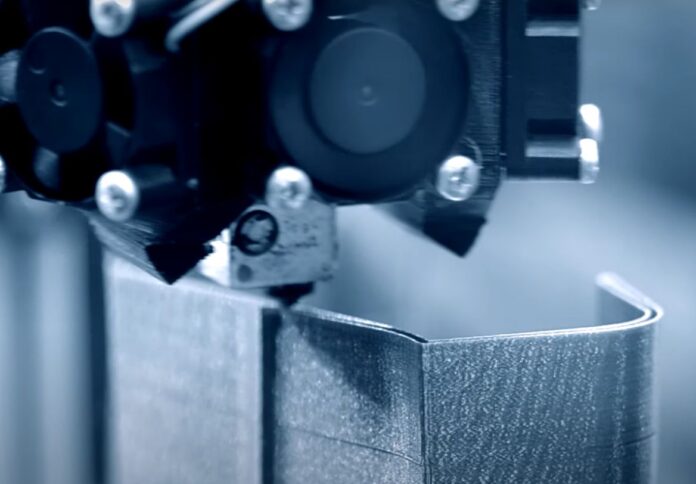

In a press release, Lockheed Martin said the new collaboration will look into additional AM technology areas, including laser powder bed fusion, electron beam-directed energy deposition, and friction-stir AM.

The partnership comes on the heels of a US government initiative dubbed as “AM Forward,” which was launched in June to strengthen US supply chains by supporting US-based suppliers’ adoption and deployment of AM.

“Sintavia and Lockheed Martin are committed to improving the capability, agility and competitiveness of the defense industrial supply base,” said Brian Neff, Sintavia’s founder and CEO. “Our partnership with Lockheed Martin seeks to identify and streamline manufacturing inefficiencies, specifically in the production of flight critical structures.”

“Lockheed Martin’s collaboration with Sintavia demonstrates our dedication to the White House’s AM Forward campaign in reducing overall operating costs and strengthening our domestic supply chain, efforts that are in line with our 21st Century Security vision,” said David Tatro, vice president for operations process transformation at Lockheed Martin.

AM touts the capability of improving efficiencies in existing castings and forgings supply chains, Lockheed Martin said. The technology also provides parts with a higher level of detail and greater design opportunities.