The Australian government must provide real support to address labour shortages in the welding industry if it seeks to continue its plans for a renewable energy revolution, according to a survey conducted by Weld Australia.

The industry representative’s latest 2023 Member Survey found that Australia’s welding and fabrication sector is facing a variety of challenges that will make the renewable energy revolution practically impossible, such as severe skills shortages and rising material and labour costs.

The survey, which saw participation from more than 130 companies, found that 60 per cent of respondents indicated that labour shortages are most likely to inhibit the growth of their business in 2023. About 45 per cent said labour shortages were their current main concern.

Furthermore, half of Australia’s welding workshops are operating at 80 per cent of their capacity or below due to a lack of skilled workers.

Geoff Crittenden, chief executive officer at Weld Australia, noted that with a large volume of work being onshored and a greater sentiment in the market to “buy local,” Australian manufacturing businesses are so short in skilled workers to the point of operating well below capacity.

“How then, will Australian fabricators cope with the influx of work required to make the Federal Government’s renewable energy revolution reality?”

As part of its renewable energy revolution plans, the Federal Government has legislated emissions reduction targets of 43 per cent on 2005 levels by 2030 and net zero by 2050.

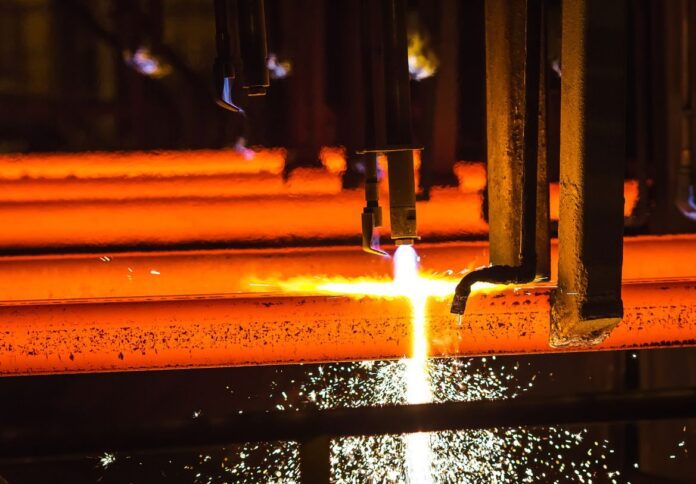

According to Weld Australia, these targets require the construction of new infrastructure on a massive scale, including over 11,000 wind towers, each requiring 500 tonnes of plate steel for onshore towers and 750 tonnes for offshore ones.

“While our governments can wish, and hope, and make public pledges about Australia’s transition to renewable energy, at the moment, we simply do not have the sovereign manufacturing capability to make this a reality,” Crittenden said.