IperionX Limited has entered into an agreement with GKN Aerospace to supply titanium plate test components manufactured using the former’s titanium technologies.

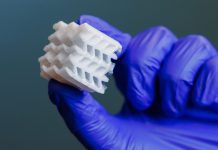

GKN Aerospace’s titanium plate components will be manufactured using IperionX’s advanced titanium angular powder and powder metallurgy techniques.

Employing its patented Hydrogen Sintering and Phase Transformation (HSPT) technologies, IperionX will enhance the microstructure of titanium, resulting in strength and fatigue properties comparable to wrought titanium alloys.

As a renowned ‘Tier-1’ aerospace supplier, GKN Aerospace plays a pivotal role in the aviation industry, servicing more than 90 per cent of the world’s aircraft and engine manufacturers, the ASX-listed company said in a press release.

IperionX said GKN Aerospace is celebrated for its innovative smart aerospace systems and components across civil aerospace, space, and military sectors.

In particular, titanium, an indispensable material in aerospace systems, is expertly manufactured by GKN Aerospace, contributing to renowned aircraft such as the Airbus A320/A330, Boeing B777/B787, Lockheed Martin F-16 and F-35 Lightning, and the Ariane 6 rocket engine.

This collaboration with GKN Aerospace is an extension of the testing and validation of IperionX’s 100 per cent recycled titanium powder, derived from GKN’s scrap titanium feedstocks.

The latest partnership zeroes in on the production of high-performance titanium plate components, which are set to undergo rigorous testing by GKN Aerospace.

Furthermore, this collaboration paves the way for potential future joint ventures between GKN Aerospace and IperionX, including projects associated with the US Department of Defence.

IperionX said it offers an extensive range of high-performance titanium powder and products, customisable to meet the demanding requirements of aerospace, defence, space, hydrogen, automotive, and consumer electronics sectors.

These advanced manufacturing capabilities encompass traditional titanium plate, bar, and rod products, as well as high-performance ‘near-net shape’ titanium components, enhancing manufacturing efficiency and sustainability.

With limited domestic primary titanium metal production capacity in the United States, the country currently relies on importing over 95 per cent of its primary titanium metal, primarily from foreign sources.

IperionX said it aims to revolutionize this paradigm by reshoring titanium mineral and metal production in the US, reducing dependence on foreign imports, and bolstering the supply chain with cost-effective and sustainable titanium products.

Taso Arima, CEO of IperionX, said GKN Aerospace is at the forefront of sustainable practices and the meticulous production of titanium components for the aerospace, space, and military sectors.

“We are very proud to be working with GKN Aerospace to commercialise our market-leading high-performance and sustainable titanium products,” he noted.