The iLAuNCH Trailblazer program is rolling out a project aimed at reducing weight in satellites through the additive manufacturing of lightweight and thermally stable composite structures.

In collaboration with the Australian National University and industry partner New Frontier Technologies, the Trailblazer program seeks to develop a material solution based on carbon fibre that will ultimately help save on the cost of accessing space.

Darin Lovett, executive director of iLAuNCH Trailblazer, said the materials and processing commercialisation project will manufacture protective coatings for carbon composite components that will be deployed in space environments for long durations.

“We are developing world-class sovereign manufacturing capability that is cost-competitive and utilises the latest advancements in materials; vital for realising the full potential of an Australian space manufacturing industry,” said Lovett.

Cost is one of the huge barriers faced by Australian companies in their efforts to reach low Earth orbit (LEO) with payloads billed per kilogram of weight by launch providers.

Furthermore, structures need to be robust to survive launch and operations in the extreme and harsh temperature environments of space.

These environmental hazards can cause surface erosion, cracking, and delamination of composite materials, which can lead to a reduction in the mechanical properties of the material, ultimately compromising the structural integrity of the spacecraft.

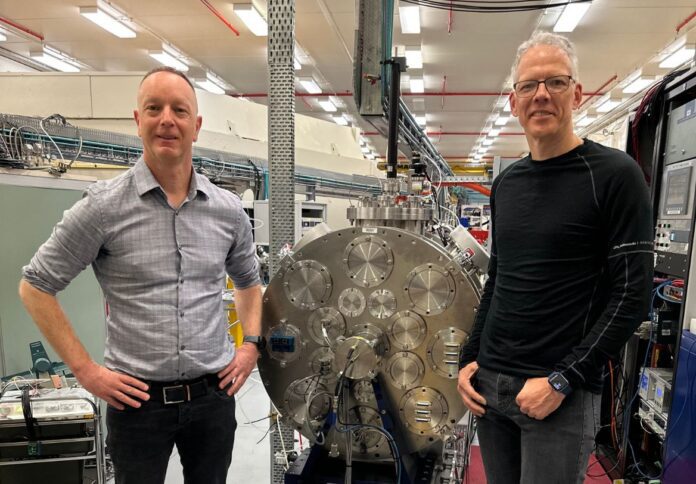

The latest iLAuNCH project will leverage material research capability in the Research School of Physics at the Australian National University, including nanomaterials fabrication and characterisation, x-ray CT imaging, and space testing capability at the Australian Advanced Instrumentation Centre at Mt Stromlo.

“The primary aim of the project is the development and validation of carbon-fibre/thermoplastic composite structures for these applications with coatings that provide improved radiation shielding and resistance to atomic oxygen degradation,” said Paul Compston, director and CEO of New Frontier Technologies.

“We will develop coating application methods that are compatible with our automated composites manufacturing technology to produce structures that are lightweight, to help to reduce launch costs, and have added protection once deployed in the harsh space environment.”

Professor Patrick Kluth from the Australian National University’s Research School of Physics said the university will use its expertise in nanomaterial science and characterisation capabilities to develop robust coatings that meet performance requirements for space applications.