Media Release

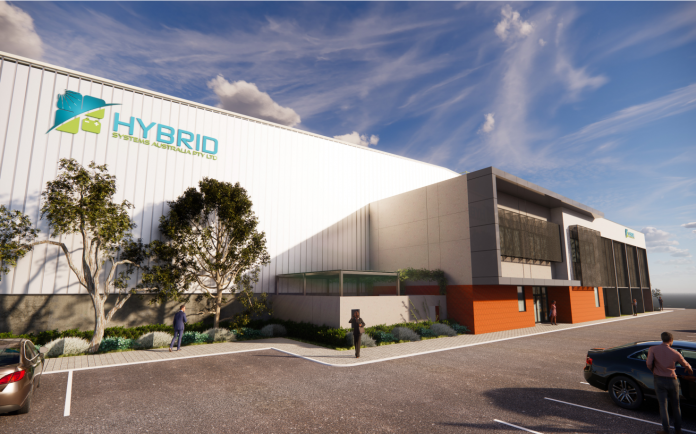

Pacific Energy’s integrated renewables subsidiary, Hybrid Systems Australia (HSA), is committing to WA’s future as a centre for renewable energy manufacturing with the announcement today of a new 16,000 square metre production facility in Perth Airport’s industrial precinct.

The new facility is understood to be the largest in the world dedicated to the design and construction of sophisticated Stand-Alone Power Systems (SPS).

Hybrid Systems Australia has taken an initial 10-year lease at the airport’s industrial precinct to house the purpose-built facility, which will step up its production capacity and to service expected requirements for SPS in the years ahead. It will also improve response times to natural disasters such as the recent bush fires and the cyclone that tore through much of the mid-West region and its infrastructure in April 2021.

The facility will house Hybrid Systems’ rapidly growing workforce of over 85 West Australian staff – up from 15 only one year ago – to design, build, operate and maintain the units. Hybrid System’s SPS units utilise world-class componentry, with all assembly conducted in-house. The company also performs all construction and testing onsite.

In a related move to bolster in-house capacity to service the growing demand for SPS in Western Australia, HSA has also agreed to purchase CPE Switchboards (“CPE”), a long-standing specialist supplier to the broader Pacific Energy group. Employing around 30 full time personnel, CPE will provide additional skills, facilities, equipment and human resources to HSA and take its personnel numbers to over 100.

The driving force behind increasing demand is Western Australian power utility Western Power. Western Power provides SPS units to customers in regional and remote locations to improve power reliability and quality as well as provide cost efficiencies. Each SPS consists of reliable renewable energy supply from solar panels, battery storage, an inverter and a backup generator. The customer is then able to draw power directly from their dedicated SPS, independent of the power grid.

In 2019, Western Power launched the first round of SPS installations with 52 fringe-of-grid customers and awarded HSA 49 of the units. HSA has now been awarded a further allocation of 60 SPS units, including 25 to assist in bringing power back to customers impacted by Cyclone Seroja, giving the company the confidence to make a long-term commitment to the new purpose-built manufacturing facility.

HSA was purchased by Australia’s biggest off-grid power company, Pacific Energy, in May last year.

Pacific Energy Chief Executive Officer Jamie Cullen noted that Western Power’s modelling showed around 6,000 viable properties where SPS units could be installed in WA over the coming decades.

“This investment is a recognition that increasing energy decentralisation and decarbonisation pressures are going to drive demand for clean energy sources such as SPS and the bigger grid-connected Battery Energy Storage Systems (BESS),” Mr Cullen said.

“This is the biggest SPS manufacturing facility in the world as far as we are aware,” he said.

“As a Perth-based national company this facility will also help us gear up to meet an estimated demand from Queensland of around 2,000 SPS units. As another big state, Queensland has the same issues as WA in terms of getting reliable power to remote customers at the edge of long power grids and the same consumer demand for renewable solutions.”

Work on the new manufacturing facility was underway and due to be completed this year, he said.

Western Power CEO Ed Kalajzic said the business was proud to be leading the nation in the roll out of SPS, providing a greener energy future for the community and supporting Australian businesses.

“Like many electricity networks around the world, Western Power is looking at ways we can improve power reliability and quality and improve operational and cost efficiencies for the community,” he said.

“We’re increasingly using renewables and SPS provides a viable alternative to traditional poles and wires while realising commercial, social, and environmental benefits.

“Our modelling shows that through installing thousands of SPS over the coming decades we could avoid millions of dollars in traditional network build, deliver customer benefits and facilitate sustainable energy.”