Biomedical engineers from the University of Melbourne have unveiled a 3D bioprinting system capable of replicating human tissues with unprecedented precision and speed.

This innovative bioprinter holds potential to reshape drug discovery, especially for cancer research, by enabling researchers to fabricate structures that closely mimic diverse tissues in the human body, from soft brain matter to harder materials like cartilage and bone, the university said in a news release.

This technology aims to advance pharmaceutical development by allowing more accurate predictions in drug testing, reducing reliance on animal testing, and expediting the research process.

Associate Professor David Collins, head of the Collins BioMicrosystems Laboratory at the University of Melbourne, described the breakthrough as a “drastic improvement” over traditional methods.

“In addition to drastically improving print speed, our approach enables a degree of cell positioning within printed tissues,” said Collins.

“Incorrect cell positioning is a big reason most 3D bioprinters fail to produce structures that accurately represent human tissue.”

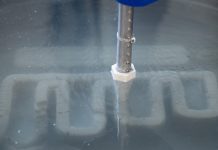

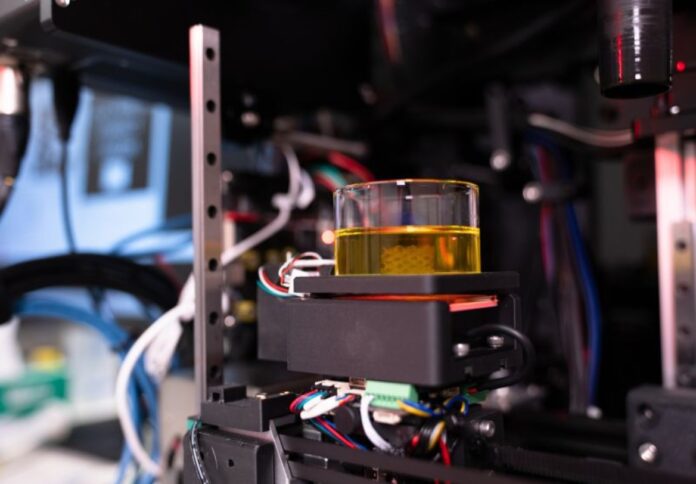

Unlike traditional 3D bioprinters that rely on slow, layer-by-layer fabrication, the University of Melbourne team has developed a system that employs acoustic waves generated by a vibrating bubble.

This innovative technique positions cells within printed structures, allowing cells to form into complex human tissues more effectively.

According to Collins, this is akin to the precise arrangement of mechanical parts in a car, which must be organised correctly to function properly.

The University of Melbourne’s method represents a major improvement over existing bioprinters, which can take hours to complete a single print.

Traditional systems often struggle to maintain cell viability due to prolonged printing times and the need to transfer fragile cell structures into laboratory plates for analysis, a process that can compromise structural integrity.

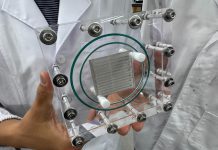

With the new bioprinter, cellular structures are completed in mere seconds — approximately 350 times faster than conventional approaches — and are printed directly into standard laboratory plates.

Researchers said this approach improves cell survival rates by eliminating the need for physical handling post-printing.

Lead researcher and PhD student Callum Vidler emphasised the growing interest within the medical research sector, citing the bioprinter’s potential to bridge the gap between lab research and clinical applications.

“Biologists recognise the immense potential of bioprinting, but until now, it has been limited to applications with a very low output,” Vidler said.

“We’ve developed our technology to address this gap, offering significant advancements in speed, precision, and consistency.”

According to Vidler, the team has engaged with approximately 60 researchers from institutions including the Peter MacCallum Cancer Centre, Harvard Medical School, and the Sloan Kettering Cancer Centre.